- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-22 Origin: Site

Efficient labeling is essential in modern packaging. In a fast-paced production environment, selecting the right automatic labeling machine is crucial. It not only optimizes your operations but also elevates the overall product appeal.

In this article, we will explore the key factors that impact your choice of an automatic labeling machine, such as product type, label compatibility, and production speed. By the end, you will understand how to make an informed decision for your packaging needs.

The shape and size of your product containers are fundamental when selecting an automatic labeling machine. Different packaging formats require different labeling techniques.

Bottles and Jars: For cylindrical items like bottles and jars, a rotary labeling machine may be ideal for its ability to quickly and precisely apply labels in high-volume settings.

Boxes and Cartons: For flat or slightly contoured packaging, an in-line labeling machine provides accuracy without needing excessive adjustments.

Irregular Shaped Containers: For products like odd-shaped containers, a machine with adjustable heads or specialized labeling methods, such as air-blow or tamp-blow applicators, is essential.

Food and Beverage: Labels need to be durable and moisture-resistant, and hygiene is critical.

Cosmetics: Precision in labeling is essential to maintain the brand’s aesthetic appeal.

Pharmaceuticals: Compliance with regulatory standards, including clear labeling, is a must.

The type of label you choose will impact the type of labeling machine you need. The most common label types are:

| Pressure-sensitive labels | Ideal for flat, smooth surfaces. They can be applied using machines that utilize wipe-on or tamp methods. |

| Shrink sleeve labels | Perfect for full-body coverage on irregularly shaped containers. These require specialized machines equipped with heat tunnels. |

| Glue-applied labels | Suitable for containers that need a strong bond but are less common in high-speed operations. |

The machine you select should be compatible with your chosen label type to avoid operational inefficiencies and labeling mistakes.

Matching the automatic labeling machine to your production needs is essential. If your production is small or medium-scale, a semi-automatic machine may suffice, allowing you to label at a slower pace with more manual intervention. However, for large-scale production requiring thousands of labels per hour, a high-speed automatic labeling machine is necessary.

Low-volume production: Semi-automatic machines or entry-level automatic machines with slower speeds are suitable.

High-volume production: High-speed machines with the ability to handle large volumes quickly will significantly improve efficiency.

Precision is one of the most important factors when choosing an automatic labeling machine. A machine with high accuracy ensures consistent label placement, which is crucial for maintaining your brand’s image. Modern machines use advanced sensors and scanners to ensure labels are applied correctly, reducing the chances of errors like misaligned or crooked labels.

For example, rotary labeling machines typically offer the highest level of precision, making them ideal for industries that require strict consistency, such as cosmetics or pharmaceuticals.

No two products are the same, and your labeling machine should be flexible enough to accommodate various shapes, sizes, and label designs. Some machines offer adjustable features that allow for quick changes between different products or packaging formats. This is especially valuable in industries with diverse product lines or seasonal promotions.

Label size adjustments

Speed and pressure settings

Applicator type settings (e.g., tamp-blow, air-blow)

Choosing a durable, reliable machine can save you money in the long run. Automatic labeling machines designed for high-volume operations should be built to last, with low maintenance requirements and the ability to run continuously without issues. Regular maintenance, however, is still necessary to ensure longevity.

Investing in a machine that offers minimal downtime is essential for maintaining production efficiency, particularly in industries with tight production deadlines.

Rotary labeling machines are designed for high-speed, large-volume production. These machines feature multiple applicators that work simultaneously to apply labels quickly and accurately.

Best for: Large production lines needing continuous, high-speed operations (e.g., beverage bottling plants).

Application: Commonly used for bottles, jars, and other cylindrical containers.

In-line labeling machines are perfect for smaller to medium-sized batches. They are ideal for containers with flat or slightly contoured surfaces. These machines provide high accuracy while being more affordable and simpler to maintain than rotary machines.

Best for: Medium-scale production, often used in industries like food, cosmetics, and pharmaceuticals.

Application: Flat, square, or rectangular containers.

Some products require more specialized labeling methods, such as shrink sleeve labels or wrap-around labels.

Shrink sleeve labelers provide full-body coverage for products and are ideal for enhancing branding with visually striking labels.

Wrap-around labelers are excellent for cylindrical containers that require labels to cover the entire circumference, making them suitable for bottles, cans, and jars.

These machines are highly adaptable to different product shapes, ensuring a secure, tamper-evident seal for your packaging.

The upfront cost of an automatic labeling machine can vary significantly, depending on factors such as machine type, speed, and customization options. Semi-automatic machines are more affordable and ideal for smaller production volumes, while automatic machines come at a higher cost but can handle large volumes efficiently.

An automatic labeling machine can reduce labor costs, improve productivity, and enhance label accuracy. These machines often provide a high ROI by speeding up production times and reducing waste caused by misapplied labels. Over time, these savings can offset the initial investment, making the machine a valuable asset for long-term operations.

While the upfront cost is important, consider the long-term costs of ownership, including maintenance, spare parts, training, and support. Choose a manufacturer who offers comprehensive warranties and service agreements, as these can save you from unexpected repair costs and downtime.

Regular cleaning is essential for maintaining the performance of your automatic labeling machine. Ensure that label paths, sensors, and rollers are free from dust and adhesive buildup. Check the quality of labels to avoid any misapplication issues.

Inspect key components, such as rollers, tamp pads, and air systems. Ensuring proper alignment and calibration will help maintain label application accuracy. Keep spare parts, like rollers and sensors, on hand to minimize downtime during production.

Label misalignment or downtime can occur if the machine isn’t properly maintained. Common issues include misfeed of labels, faulty sensors, or poor adhesive performance. Always refer to the machine’s troubleshooting guide for quick fixes, and consider investing in preventative maintenance.

Choosing the right automatic labeling machine is essential for efficient production. Factors like product type, label compatibility, machine features, and speed should guide your decision. The right machine can boost efficiency, ensure product quality, and maintain brand integrity.

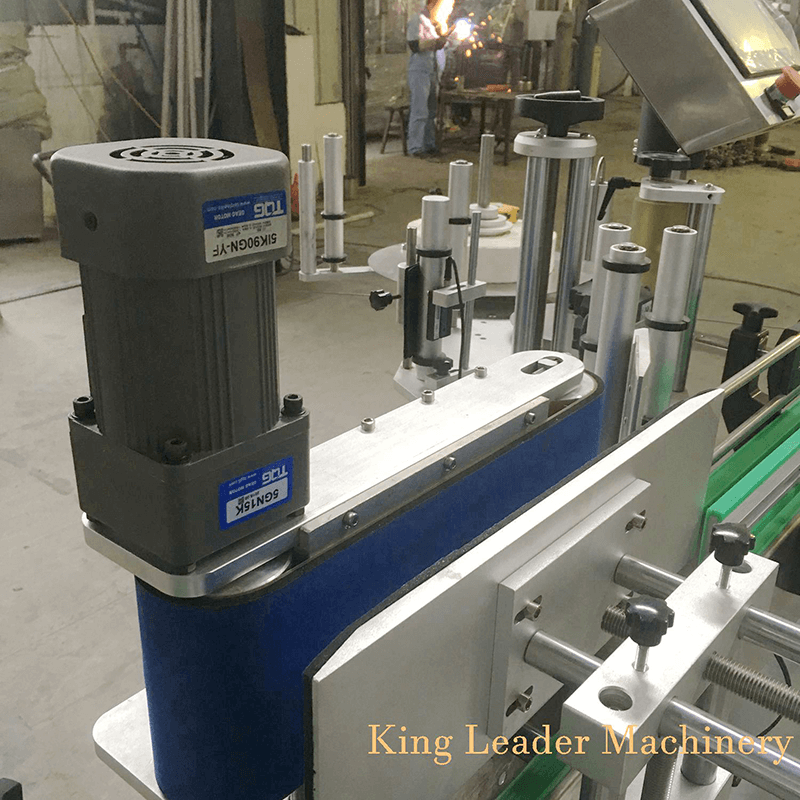

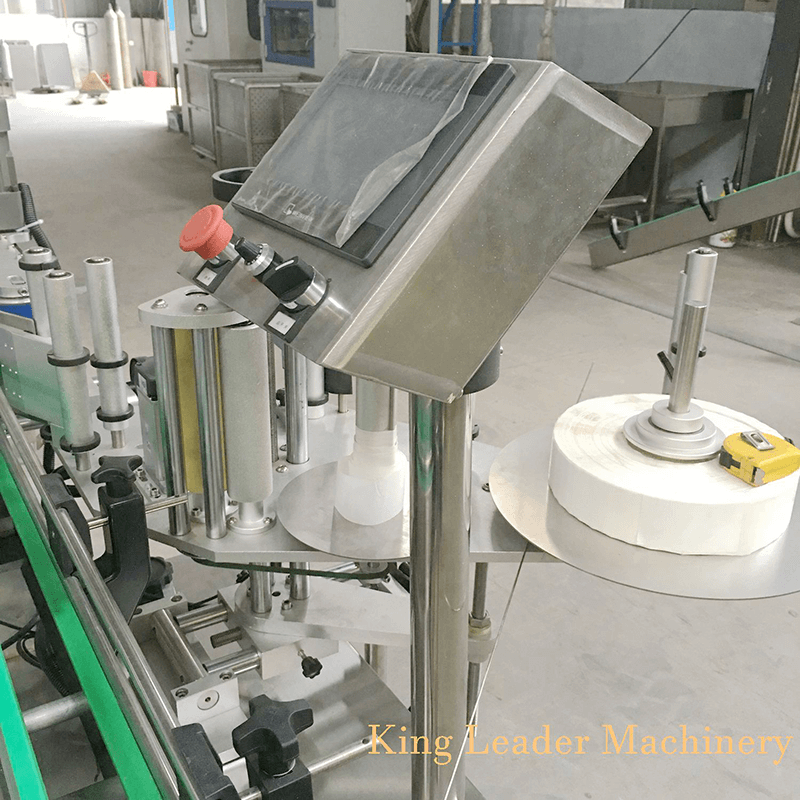

King Leader offers reliable labeling machines tailored to your production needs. Their products provide high accuracy and flexibility, ensuring consistent labeling while helping you scale efficiently.

A: An automatic labeling machine is a device used to apply labels to products or packaging without manual intervention, ensuring consistency and speed in production.

A: Consider factors like product type, label material, production speed, and the specific labeling method (e.g., pressure-sensitive, shrink sleeve) to choose the best machine for your needs.

A: Automatic labeling machines increase efficiency, reduce labor costs, improve accuracy, and help maintain consistent product quality.

A: The cost varies depending on the machine’s features, speed, and customization options. Generally, automatic labeling machines are more expensive than semi-automatic ones but offer higher productivity.