- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-18 Origin: Site

Hot Melt Glue Labeling Machines are essential equipment in the packaging industry, offering a highly efficient and reliable solution for applying labels to various products. These machines use hot melt adhesive to bond labels to containers, providing a strong and durable hold that ensures the labels stay intact throughout the product’s lifecycle. The increasing demand for fast and efficient labeling systems has driven the growth of hot melt glue labeling machines across industries like food and beverage, pharmaceuticals, cosmetics, and home care products. This technology stands out for its ability to deliver high-quality results at high speeds, making it a popular choice for manufacturers looking to streamline production while maintaining label integrity. In this guide, we’ll explore the benefits, applications, and future trends of hot melt glue labeling machines, shedding light on why they are a cornerstone of modern packaging solutions.

Hot melt glue labeling technology involves the use of hot melt adhesive to apply labels to containers in a precise and durable manner. Unlike traditional methods, which rely on solvent-based or water-based adhesives, hot melt glue is applied when heated to a molten state, offering a quicker setting time and stronger bond once cooled. This technology is widely used in industries where high-speed, high-quality labeling is critical, such as food and beverage, pharmaceuticals, and cosmetics.

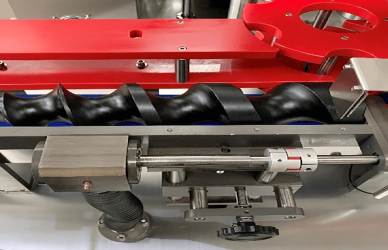

In a hot melt glue labeling machine, the process starts with the application of molten adhesive onto either the label or the container. The adhesive is typically stored in a heated tank, and as the labels are fed into the machine, a precisely controlled nozzle applies the hot glue to the surface. Once the adhesive is applied, the label is placed onto the container, and the adhesive cools quickly, forming a strong bond that holds the label in place. This rapid cooling process ensures that the labels stay intact and do not shift during packaging or transportation.

Hot melt glue labeling machines differ from other types of labeling systems, such as pressure-sensitive and cold glue labeling machines, in several ways:

Pressure-Sensitive Labeling Machines: These systems use self-adhesive labels that are activated by pressure, meaning no heat or glue is required. While suitable for a wide range of applications, pressure-sensitive systems are generally slower and can result in higher costs due to the adhesive properties of the labels themselves.

Cold Glue Labeling Machines: Cold glue systems apply water-based adhesives to labels, which then adhere to containers. While this method can be more cost-effective, it often requires longer drying times, can be messy, and may not offer the same strong bond as hot melt glue. Cold glue also has limitations in high-speed environments due to slower setting times.

Hot melt glue labeling machines offer cost efficiency by reducing material waste and energy consumption. The precise application of hot melt glue minimizes excess use, while the quick setting time reduces the need for energy-intensive drying processes. This makes them ideal for high-volume production environments, where cost control is crucial.

Hot melt glue creates a strong, durable bond that lasts over time. It’s resistant to temperature changes, humidity, and rough handling, making it ideal for products that face challenging conditions. This high adhesion strength ensures labels stay intact throughout distribution and use.

These machines can label at high speeds, significantly improving productivity. The fast application and quick cooling of hot melt glue allow for high-volume production lines to run smoothly, meeting the demands of fast-paced industries.

Hot melt glue labeling machines are versatile, capable of labeling various container types such as glass, plastic, and metal. This flexibility allows businesses to label a wide range of products efficiently and consistently, making it ideal for companies with diverse packaging needs.

Hot melt glue systems are more eco-friendly than traditional methods because they use environmentally friendly adhesives and reduce the use of harmful solvents. This minimizes the release of volatile organic compounds (VOCs), offering a safer and cleaner option for both workers and the environment.

In the food and beverage industry, hot melt glue labeling machines ensure clean and secure labeling on containers like glass and plastic bottles, jars, and cans. The strong adhesive properties of hot melt glue keep labels intact during handling, transportation, and storage, even in humid or cold environments. This makes it ideal for high-volume production lines where labeling consistency and quality are crucial.

The pharmaceutical industry requires high-precision labeling for medicine and health-related products. Hot melt glue labeling machines provide reliable, accurate labeling that meets stringent regulatory standards. These machines are designed to apply labels precisely, ensuring that they remain securely in place while meeting compliance requirements for packaging, tamper-evidence, and product information.

In the cosmetics and personal care industry, hot melt glue labeling is used for products packaged in jars, bottles, and tubes. The durability of hot melt glue is ideal for labeling products that are often handled or exposed to moisture, ensuring that the labels stay intact throughout the product's use. Additionally, the high-quality bond helps maintain the appearance of the product, contributing to a premium look and feel.

For home care and chemical products, such as cleaning products, detergents, and other household items, hot melt glue labeling machines provide reliable and efficient labeling solutions. The strong adhesive ensures labels stay securely affixed to containers, even when exposed to challenging conditions like heat, moisture, or handling. These machines support high-speed production and consistent labeling, essential for large-scale manufacturing in this industry.

One common challenge with hot melt glue labeling machines is the over-application or under-application of glue, which can lead to issues such as excess glue on labels or insufficient adhesion. To overcome this, it is essential to properly calibrate the glue application system, ensuring the correct amount of adhesive is applied consistently. Regular monitoring and adjustment of glue temperature and flow rates can also help maintain optimal application levels. Using quality adhesives designed for specific labeling tasks will reduce application errors.

Achieving precise label placement can be challenging, especially when labeling high-speed production lines with varying container shapes and sizes. To address this, sensors and alignment guides should be used to automatically adjust the label positioning during the labeling process. Incorporating vision systems can also help verify label accuracy and alignment, ensuring that labels are placed precisely and consistently every time.

Maintenance is crucial to avoid unexpected downtime in hot melt glue labeling machines, as wear and tear on parts like the glue tank, nozzles, and rollers can lead to malfunctions. Regular cleaning and inspection of the machine are necessary to prevent buildup and ensure smooth operation. Scheduled maintenance, such as checking the glue application system and replacing worn components, helps prevent breakdowns and ensures consistent performance. Additionally, maintaining a stock of spare parts for quick replacements can minimize production delays.

Hot melt glue provides a stronger and more durable bond, faster setting times, and less risk of damage to labels and containers compared to pressure-sensitive adhesives or cold glue.

The fast drying time and continuous operation of hot melt glue labeling machines allow for high-speed production lines, significantly increasing throughput and reducing downtime.

Yes, hot melt glue labeling machines are versatile and can be used on a variety of containers, including glass, plastic, metal, and composite materials, making them ideal for diverse industries.

Hot melt glue labeling machines are more eco-friendly than traditional labeling systems because they use less solvent-based adhesives and produce fewer volatile organic compounds (VOCs), supporting sustainability efforts in packaging.

Hot melt glue labeling machines have become an indispensable tool in modern packaging operations, offering significant advantages such as cost efficiency, high adhesion strength, speed, and versatility. These machines are critical in industries like food and beverage, pharmaceuticals, cosmetics, and home care products, where consistent and durable labeling is essential. However, challenges such as glue application issues, label alignment, and the risk of downtime still exist. By properly calibrating the glue application system, using advanced alignment guides and vision systems, and adhering to regular maintenance schedules, businesses can overcome these challenges and optimize machine performance. Ensuring smooth operation not only helps improve efficiency but also reduces costly production delays. In the long run, hot melt glue labeling machines provide reliable, high-speed labeling solutions that are crucial for maintaining product quality and boosting productivity, making them a key asset in the packaging industry’s continued evolution.