- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-12-22 Origin: Site

Selecting the right Hot Melt Labeling Machine is crucial for high-volume production environments, where efficiency, precision, and reliability are key. Hot melt labeling technology offers numerous advantages, including strong adhesion, fast application speeds, and minimal waste, making it an ideal choice for industries such as food and beverage, cosmetics, pharmaceuticals, and more. These machines use hot melt adhesives that cool rapidly, creating a durable bond between the label and the container, ensuring that the label remains intact throughout distribution and use. When choosing a machine for high-volume applications, it is essential to consider factors such as production speed, container compatibility, labeling accuracy, and maintenance needs to ensure seamless operation and maximum productivity. The right choice will not only enhance operational efficiency but also contribute to cost savings and quality control.

Production speed is a key factor when selecting a hot melt labeling machine. It’s crucial to choose a machine that meets the required speed for your production line, capable of handling high volumes without compromising on quality.

Ensure that the machine can handle a variety of container shapes and sizes such as bottles, cans, and jars. The ability to accommodate diverse packaging types improves versatility and flexibility in production.

High-quality labeling depends on label alignment systems and precise adhesive application. The machine should provide accurate glue application and ensure labels are aligned correctly to avoid misplacement or waste.

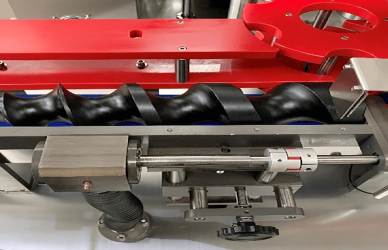

The glue application system, including the tank, nozzles, and temperature control, is critical for consistent results. Proper temperature control ensures effective glue adhesion and reduces waste.

Choose a machine that is easy to clean and maintain, minimizing downtime and ensuring smooth, continuous operation. Regular maintenance is key to sustaining performance and avoiding breakdowns.

Consider the energy consumption of the machine to assess its operational costs. Energy-efficient machines reduce electricity use, cutting long-term costs while supporting sustainability goals.

Wrap-around labeling machines are designed for cylindrical containers, making them ideal for labeling bottles, cans, and other round-shaped packaging. These machines apply labels that wrap completely around the container, ensuring full coverage and consistent adhesion. Wrap-around machines are commonly used in industries like beverages and food packaging, where high-speed and high-volume labeling is essential.

Top and bottom labeling machines are ideal for containers with flat surfaces such as jars, boxes, or tubs. These machines can label both the top and bottom of containers in one pass, making them perfect for products that require dual-labeling, like cosmetics or pharmaceuticals. This type of labeling is highly efficient, especially for products with smaller packaging and precise labeling needs.

Rotary labeling machines are designed for high-speed applications and can label a variety of container types with precision and consistency. These machines operate using a rotating mechanism, making them suitable for large-scale production lines where speed and accuracy are paramount. They are commonly used in industries with high-throughput needs, such as beverages, personal care, and household goods.

Inline labeling machines are designed for continuous production lines, where both speed and space efficiency are critical. These machines apply labels as the containers move along a conveyor system, ensuring a smooth and seamless labeling process. Ideal for high-volume environments, inline labeling machines are used in industries such as food, beverages, and cleaning products where consistent, uninterrupted labeling is necessary for maximum efficiency.

When considering a hot melt labeling machine for high-volume production, evaluating its cost-effectiveness involves looking at both the initial investment and the long-term operational costs. Machines that offer higher speed, reduced waste, and greater efficiency can significantly reduce per-unit costs, which makes them more cost-effective in high-volume production environments. It’s important to assess the upfront cost in relation to the potential savings over time.

To calculate the Return on Investment (ROI) for a hot melt labeling machine, several factors must be considered:

Labor Savings: Automating the labeling process reduces the need for manual labor, lowering labor costs and increasing overall productivity. The ROI is positively impacted by these savings, as fewer employees are required to perform the same task.

Material Waste Reduction: Hot melt glue systems offer precise adhesive application, minimizing waste and reducing costs associated with excess glue or rework. Lower material costs contribute directly to the ROI, especially in industries where label and adhesive materials can be expensive.

Speed and Throughput: The speed at which the machine operates directly impacts ROI. Faster labeling processes mean higher throughput, reducing the time it takes to produce each unit and improving the overall efficiency of the production line.

Machine Longevity: A machine that requires fewer repairs and lasts longer delivers a better ROI. The initial cost can be amortized over time, especially when coupled with reliable performance and low maintenance requirements.

Choosing a hot melt labeling machine often involves weighing trade-offs between initial cost, operational cost, and long-term performance:

Initial Cost: While a high-quality machine with advanced features may have a higher upfront cost, it can offer greater benefits in terms of durability, speed, and efficiency, ultimately leading to better long-term returns.

Operational Costs: Machines that are energy-efficient and require minimal maintenance can help keep operational costs low, increasing the overall ROI. Machines with higher energy consumption or complex maintenance needs may result in higher operating costs over time.

Long-Term Performance: Investing in a machine that offers reliable performance and has low wear-and-tear can provide consistent returns over an extended period, making it more cost-effective in the long run. It’s important to evaluate how the machine will perform in the long term, factoring in warranty periods, service availability, and expected maintenance needs.

When selecting a hot melt labeling machine, it’s crucial to ensure compatibility with your existing production equipment and workflows. Seamless integration minimizes disruptions, reducing retraining time and setup costs, while ensuring smooth operation across the entire production line.

The hot melt labeling machine should integrate easily with other key production systems, such as conveyor belts, filling stations, and packaging machines. Proper synchronization ensures continuous production flow, accurate labeling, and minimized downtime, leading to enhanced overall efficiency.

For unique labeling needs or specialized container designs, hot melt labeling machines offer customization options. These can include adjustable label sizes, multiple labeling positions, and the ability to handle various container shapes, providing flexibility for different industries and product specifications.

To keep hot melt labeling machines running efficiently in high-volume settings, regular maintenance is essential. Key tasks include cleaning glue tanks, checking nozzles for blockages, and monitoring temperature controls to ensure consistent glue application. Lubricating moving parts and inspecting critical components for wear can also prevent unexpected breakdowns and extend the life of the machine.

Having access to reliable technical support is crucial for addressing issues promptly and minimizing downtime. Ensure that the machine manufacturer or supplier offers readily available replacement parts to avoid delays. Many manufacturers also provide warranties that cover defects and certain repairs, offering peace of mind and protection for your investment.

To avoid unnecessary downtime, setting up a preventive maintenance schedule is key. This includes routine inspections, cleaning, and part replacements based on the manufacturer’s guidelines. Scheduling maintenance during off-peak hours or planned production breaks helps prevent disruptions. By adhering to a preventive maintenance plan, you can keep the machine running at peak performance and avoid costly repairs caused by neglected maintenance.

Consider the required labeling speed to match your production line’s throughput. Machines capable of labeling thousands of containers per hour are ideal for high-volume settings.

Yes, many hot melt labeling machines are designed to handle a variety of container types (e.g., glass, plastic, metal), but it’s essential to choose a machine with adjustable settings to accommodate the sizes and shapes of your containers.

To calculate ROI, consider factors like production speed, material savings, and maintenance costs. A machine that reduces labeling time and adhesive waste can lead to significant long-term savings.

Regular maintenance includes cleaning glue tanks, checking nozzle performance, and monitoring temperature controls. Having a clear maintenance schedule and access to technical support will ensure smooth operation and prevent downtime.

Choosing the right hot melt labeling machine is crucial to ensure optimal performance and efficiency in high-volume production. The right machine can enhance productivity, reduce operational costs, and maintain consistent label quality, all while meeting the specific demands of your production line. It’s important to balance factors such as speed, cost, precision, and maintenance when making your decision. While a higher initial investment may be required for machines with advanced features, the long-term benefits in terms of efficiency and reduced downtime can make it worthwhile. Consulting with experts or manufacturers can help you find the best fit for your unique production needs, ensuring that you select a machine that delivers maximum value and supports sustainable growth in your operations.