- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-20 Origin: Site

As environmental concerns rise, consumers increasingly prefer eco-friendly packaging. This shift is pressuring brands to adopt sustainable solutions, especially in shrink wrapping.

Shrink wrapping, once known for its efficiency, is evolving to meet sustainability expectations. In this article, we’ll discuss how eco-friendly shrink wrapping machines are transforming the industry. You’ll learn about the materials used, the benefits of sustainable packaging, and how businesses can make the transition to greener solutions.

Consumers today are more aware than ever of the environmental consequences of their choices. Recent surveys show that a significant portion of shoppers are willing to pay more for products with sustainable packaging. This shift is particularly strong among Millennials and Gen Z, who are highly motivated by sustainability.

The impact of eco-friendly packaging goes beyond the consumer's choice; it influences brand perception and loyalty. In fact, 90% of consumers indicate that they are more likely to purchase from brands that prioritize sustainability. This growing demand is reshaping packaging strategies, compelling businesses to invest in greener packaging solutions.

Governments worldwide are tightening regulations around plastic use and packaging waste. For instance, the European Union has implemented stringent laws to reduce single-use plastics, pushing industries to seek more sustainable alternatives. In the U.S., several cities have already banned Styrofoam, and the federal government is following suit with more recycling mandates.

These regulatory efforts are driving the adoption of sustainable packaging solutions. As a result, brands are not only motivated by consumer preferences but are also legally obligated to transition towards more eco-friendly packaging materials.

Sustainable packaging reduces waste, conserves natural resources, and minimizes pollution. By switching to biodegradable or recyclable materials, businesses can significantly reduce their environmental footprint. Moreover, sustainable packaging supports the circular economy by promoting the reuse and recycling of materials, which lowers overall resource consumption.

Shrink wrapping is a key part of this shift, with manufacturers increasingly offering films made from renewable sources that are easier to recycle or compost. The environmental benefits of these alternatives cannot be overstated, particularly as the demand for greener products continues to rise.

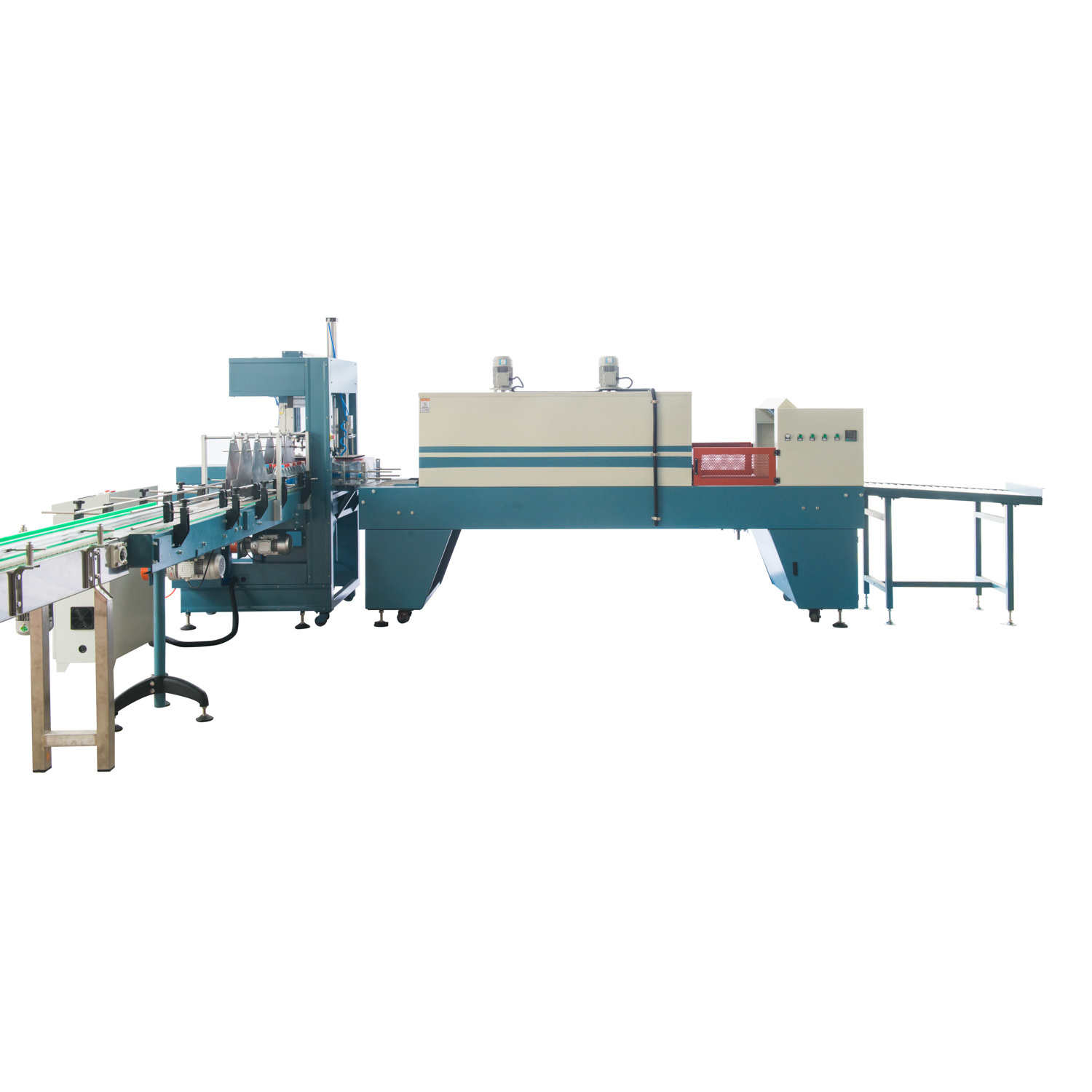

Eco-friendly shrink wrapping machines are designed to use materials that minimize environmental impact. Unlike traditional machines that might rely on plastic films made from petroleum-based resources, eco-friendly alternatives utilize biodegradable, recyclable, or even compostable films. These machines are also designed to optimize energy consumption, reducing their carbon footprint.

The key difference between conventional and eco-friendly shrink wrapping machines lies in their material usage and production processes. Eco-friendly machines ensure that not only the shrink films but also the machines themselves, are designed with sustainability in mind.

When upgrading to eco-friendly shrink wrapping machines, ensure that both the films and the machines meet sustainability standards to maximize environmental benefits.

When selecting an eco-friendly shrink wrapping machine, consider the following features:

Energy-efficient systems: Machines that use less power to operate will significantly reduce your overall energy consumption.

Compatibility with sustainable films: The machine should be capable of handling recyclable and biodegradable films without compromising efficiency.

Material waste reduction technologies: Look for features that minimize film waste during the packaging process, ensuring that every piece of material is used efficiently.

These features are critical for ensuring that the shrink wrapping process aligns with a company’s sustainability goals.

Several materials are commonly used in eco-friendly shrink wrapping, including:

Polyethylene (PE): A widely used plastic that is recyclable and offers good strength and durability.

Polyolefin (POF): Known for its flexibility and ability to shrink tightly, POF is often used for food packaging and is available in recyclable forms.

Biodegradable Films: Some manufacturers are now offering films made from plant-based materials that decompose naturally over time.

The trend is shifting towards using recycled content in these materials, further reducing the demand for new raw materials.

Select shrink films that align with your sustainability goals, such as biodegradable or recyclable options, to enhance your eco-friendly practices.

When choosing an eco-friendly shrink wrapping machine, it is essential to evaluate your production needs. Consider the scale of your operations—whether you're a small, medium, or large business—since this will determine the capacity and features you require.

Also, align the machine's capabilities with your environmental goals. If waste reduction is a priority, ensure the machine is optimized for minimizing material usage. Similarly, if you’re looking to reduce carbon emissions, select energy-efficient machines.

While eco-friendly shrink wrapping machines may have a higher upfront cost, their long-term benefits far outweigh the initial investment. These machines typically offer lower operational costs due to reduced material waste and energy consumption. Additionally, they contribute to reducing waste disposal costs, as many eco-friendly materials are recyclable or biodegradable.

By assessing the total cost of ownership (TCO) and comparing it with the savings from lower waste and energy bills, you can calculate a positive return on investment (ROI).

Tips: When calculating ROI, factor in long-term savings from energy efficiency and material waste reduction to better understand the machine’s value.

Key technical considerations include:

| Automatic film tracking | This feature ensures precise and consistent film application, reducing waste. |

| Sealing capabilities | Look for machines that provide secure, tamper-evident seals without excessive material use. |

| Integration with existing lines | Ensure the machine integrates seamlessly with your current packaging system for efficiency. |

These features enhance the machine's overall performance and ensure that it supports both your sustainability and operational efficiency goals.

The future of shrink wrapping is moving toward increased automation and smarter packaging solutions. Innovations like AI and machine learning are being applied to improve material efficiency, helping businesses minimize waste while maintaining high product quality.

Additionally, the development of smart films, which can indicate spoilage or temperature changes, is an exciting trend that could revolutionize packaging, particularly in the food industry.

Stay ahead of the curve by exploring emerging technologies like AI-driven machines and smart films that contribute to sustainability goals.

Many brands are already making the transition to eco-friendly shrink wrapping machines. Case studies show how companies have successfully reduced their environmental footprint by switching to recyclable films and energy-efficient machinery. These brands are also improving their market competitiveness by aligning with consumer values on sustainability.

For businesses looking to enhance their green credentials, transitioning to eco-friendly shrink wrapping is a crucial step toward future-proofing their operations.

Sustainable packaging has become essential for businesses. The rise of eco-friendly shrink wrapping machines addresses consumer demands and regulatory pressures. Investing in these machines helps reduce environmental impact, improve efficiency, and meet consumer expectations.

Switching to eco-friendly shrink wrapping machines may require an initial investment, but the long-term financial and environmental benefits are clear. King Leader's products, with their efficient and sustainable features, can help businesses align with sustainability goals, improving brand loyalty and compliance.

A: An eco-friendly shrink wrapping machine uses sustainable materials like recyclable or biodegradable films to minimize environmental impact while packaging products.

A: Shrink wrapping machines reduce material waste and energy consumption, helping businesses lower their carbon footprint and support sustainable packaging practices.

A: While the initial investment may be higher, eco-friendly shrink wrapping machines offer long-term savings through reduced material costs and improved efficiency.

A: Common materials include recyclable polyethylene, polyolefin, and biodegradable films, all of which help reduce packaging waste.