- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

CGF18-18-6

kld

Specification:

Our rinsing machine ensures thorough and efficient bottle cleaning with advanced features designed for high performance and hygiene.

Key Features:

180° Bottle Rotation:

Spring cramps rotate bottles 180° along the rail, enabling internal and external washing for maximum cleanliness.

Durable Bottle Clips:

Made of SUS304 stainless steel, our double-opened bottle clips securely hold bottles during rinsing, ensuring hygiene and durability.

Efficient Spray Nozzles:

Equipped with 15° angled spray nozzles, the machine cleans every side of the bottle while saving water.

Stainless Steel Construction:

Built from high-quality stainless steel, the machine is durable and easy to maintain.

Bottle Jam Protection:

Includes a jam protection device to prevent disruptions and keep operations running smoothly.

Picture of Rinsing Part

2. Filling Part

Filling Part: Precision and Efficiency

Our filling machine ensures accurate, hygienic, and stable performance for your production needs.

Key Features:

Optimized Design:

Eliminates hygiene dead angles for a clean and efficient operation.

Precision Control:

Controls material flow with ±2mm accuracy (depending on bottle design) for consistent fills.

High-Quality Materials:

Filling valve made from SUS304 stainless steel ensures durability and hygiene.

Automatic Liquid Level Control:

Ensures precise fills and reduces waste.

Valve Elevator System:

Starts filling when the valve contacts the bottleneck for seamless operation.

Smooth Conveying:

Bottles are conveyed smoothly using a wheel system.

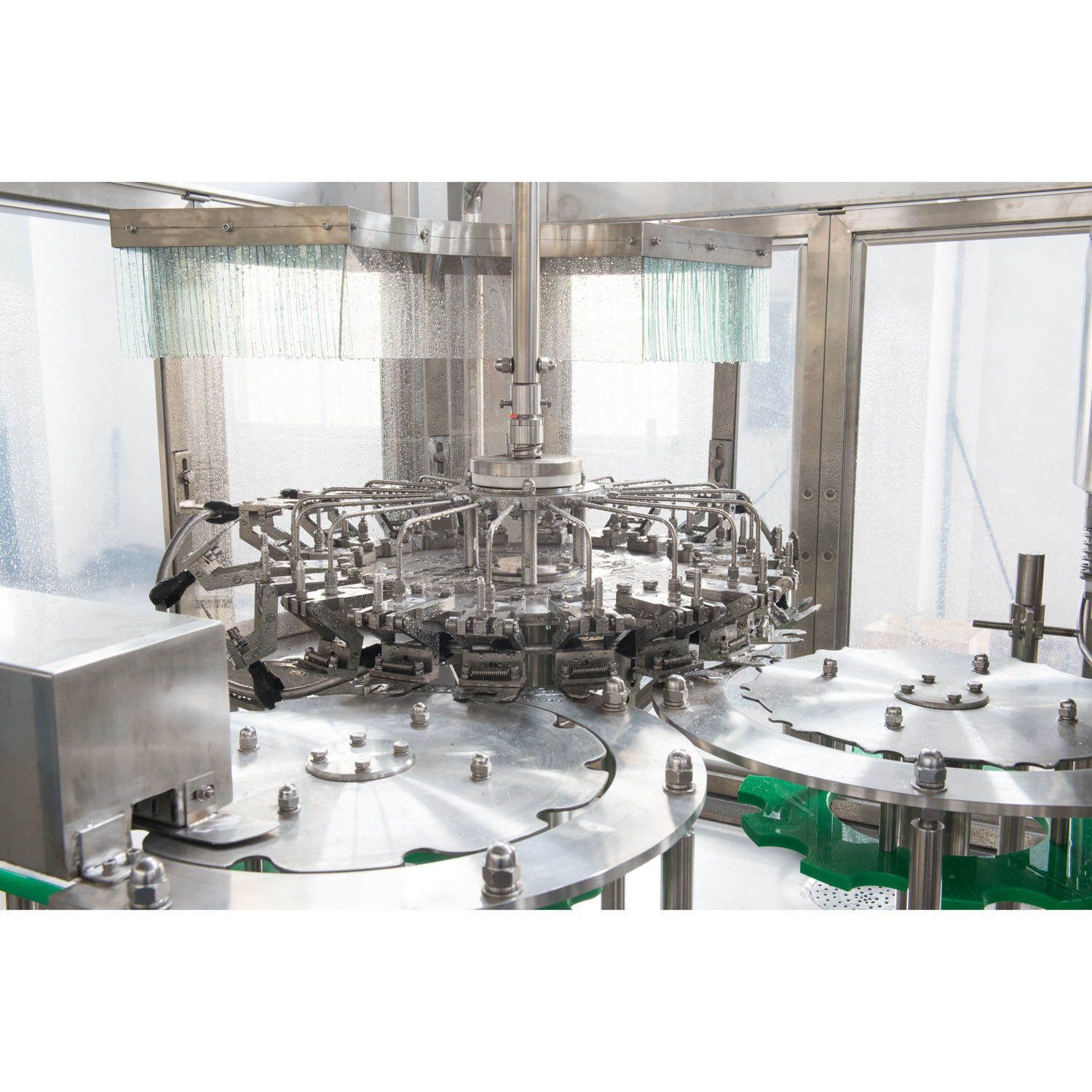

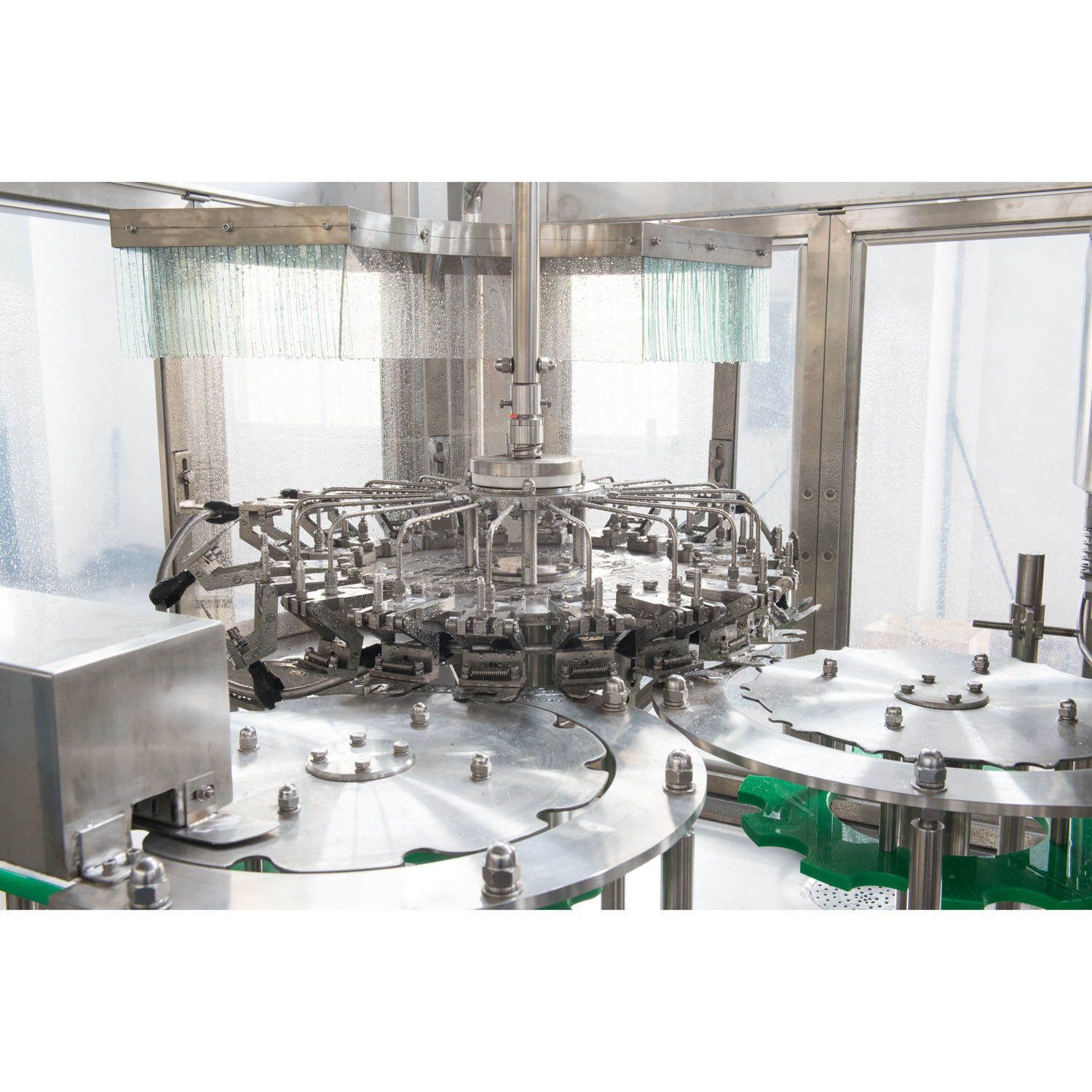

Picture of Filling Part

Capping Parts: Precision and Reliability

The screw capping machine is a critical component of the 3-in-1 machine, ensuring product stability and minimizing defects. Our system delivers precision and reliability for secure sealing every time.

Key Features:

High Precision: Ensures consistent and secure seals.

Product Stability: Protects against contamination and leakage.

Reduced Defects: Lowers defective rates for higher quality.

Versatile: Adapts to various bottle and cap types.

Durable: Built for long-lasting performance.

Picture of capping Part

Electrical configuration

PLC: MITSUBISHI

Touch Screen: MITSUBISHI

Transducer: MITSUBISHI

Contactor: SCHNEIDER

Pneumatic Parts: AIRTAC

NOTE: All these parts can be changed as customer specify.

Technical Parameter:

| Model | XGF16-12-6 | XGF18-18-6 | XGF24-24-8 | XGF32-32-10 | XGF40-40-12 | XGF50-50-15 | XGF60-60-15 |

| Production capacity (b/h) | 2000-4000 | 5000-6000 | 6000-10000 | 10000-13000 | 13000-15000 | 15000-20000 | 20000-24000 |

| Bottle size (mm) | φ=50-110mm, H=170-310mm (Volume: 200-2000ml) | ||||||

| Main Motor power | 4.0kw | 4.2kw | 5.2kw | 6.2kw | 7.5kw | 8.2kw | 9.5kw |

| Dimension (m, L x W x H) | 2.23×1.63×2.25 | 2.6×1.965×2.25 | 2.9×2.2×2.25 | 3.88×2.2×2.25 | 3.7×3.0×2.35 | 4.5×3.5×2.35 | 5.5×4.5×2.35 |

| Weight (Kg) | 2500 | 3500 | 4200 | 6000 | 7000 | 7600 | 9800 |

Specification:

Our rinsing machine ensures thorough and efficient bottle cleaning with advanced features designed for high performance and hygiene.

Key Features:

180° Bottle Rotation:

Spring cramps rotate bottles 180° along the rail, enabling internal and external washing for maximum cleanliness.

Durable Bottle Clips:

Made of SUS304 stainless steel, our double-opened bottle clips securely hold bottles during rinsing, ensuring hygiene and durability.

Efficient Spray Nozzles:

Equipped with 15° angled spray nozzles, the machine cleans every side of the bottle while saving water.

Stainless Steel Construction:

Built from high-quality stainless steel, the machine is durable and easy to maintain.

Bottle Jam Protection:

Includes a jam protection device to prevent disruptions and keep operations running smoothly.

Picture of Rinsing Part

2. Filling Part

Filling Part: Precision and Efficiency

Our filling machine ensures accurate, hygienic, and stable performance for your production needs.

Key Features:

Optimized Design:

Eliminates hygiene dead angles for a clean and efficient operation.

Precision Control:

Controls material flow with ±2mm accuracy (depending on bottle design) for consistent fills.

High-Quality Materials:

Filling valve made from SUS304 stainless steel ensures durability and hygiene.

Automatic Liquid Level Control:

Ensures precise fills and reduces waste.

Valve Elevator System:

Starts filling when the valve contacts the bottleneck for seamless operation.

Smooth Conveying:

Bottles are conveyed smoothly using a wheel system.

Picture of Filling Part

Capping Parts: Precision and Reliability

The screw capping machine is a critical component of the 3-in-1 machine, ensuring product stability and minimizing defects. Our system delivers precision and reliability for secure sealing every time.

Key Features:

High Precision: Ensures consistent and secure seals.

Product Stability: Protects against contamination and leakage.

Reduced Defects: Lowers defective rates for higher quality.

Versatile: Adapts to various bottle and cap types.

Durable: Built for long-lasting performance.

Picture of capping Part

Electrical configuration

PLC: MITSUBISHI

Touch Screen: MITSUBISHI

Transducer: MITSUBISHI

Contactor: SCHNEIDER

Pneumatic Parts: AIRTAC

NOTE: All these parts can be changed as customer specify.

Technical Parameter:

| Model | XGF16-12-6 | XGF18-18-6 | XGF24-24-8 | XGF32-32-10 | XGF40-40-12 | XGF50-50-15 | XGF60-60-15 |

| Production capacity (b/h) | 2000-4000 | 5000-6000 | 6000-10000 | 10000-13000 | 13000-15000 | 15000-20000 | 20000-24000 |

| Bottle size (mm) | φ=50-110mm, H=170-310mm (Volume: 200-2000ml) | ||||||

| Main Motor power | 4.0kw | 4.2kw | 5.2kw | 6.2kw | 7.5kw | 8.2kw | 9.5kw |

| Dimension (m, L x W x H) | 2.23×1.63×2.25 | 2.6×1.965×2.25 | 2.9×2.2×2.25 | 3.88×2.2×2.25 | 3.7×3.0×2.35 | 4.5×3.5×2.35 | 5.5×4.5×2.35 |

| Weight (Kg) | 2500 | 3500 | 4200 | 6000 | 7000 | 7600 | 9800 |