- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

CGF18-18-6

kld

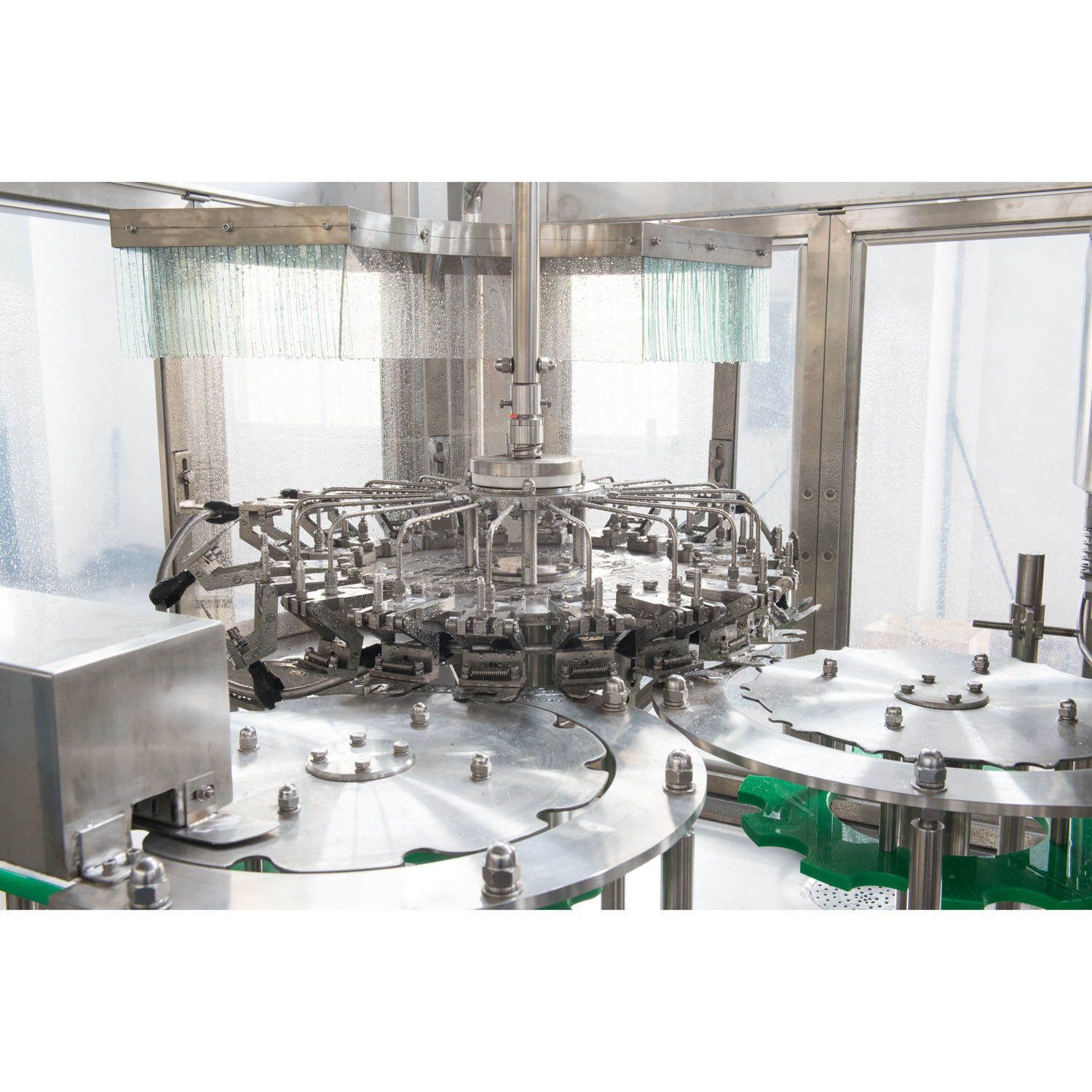

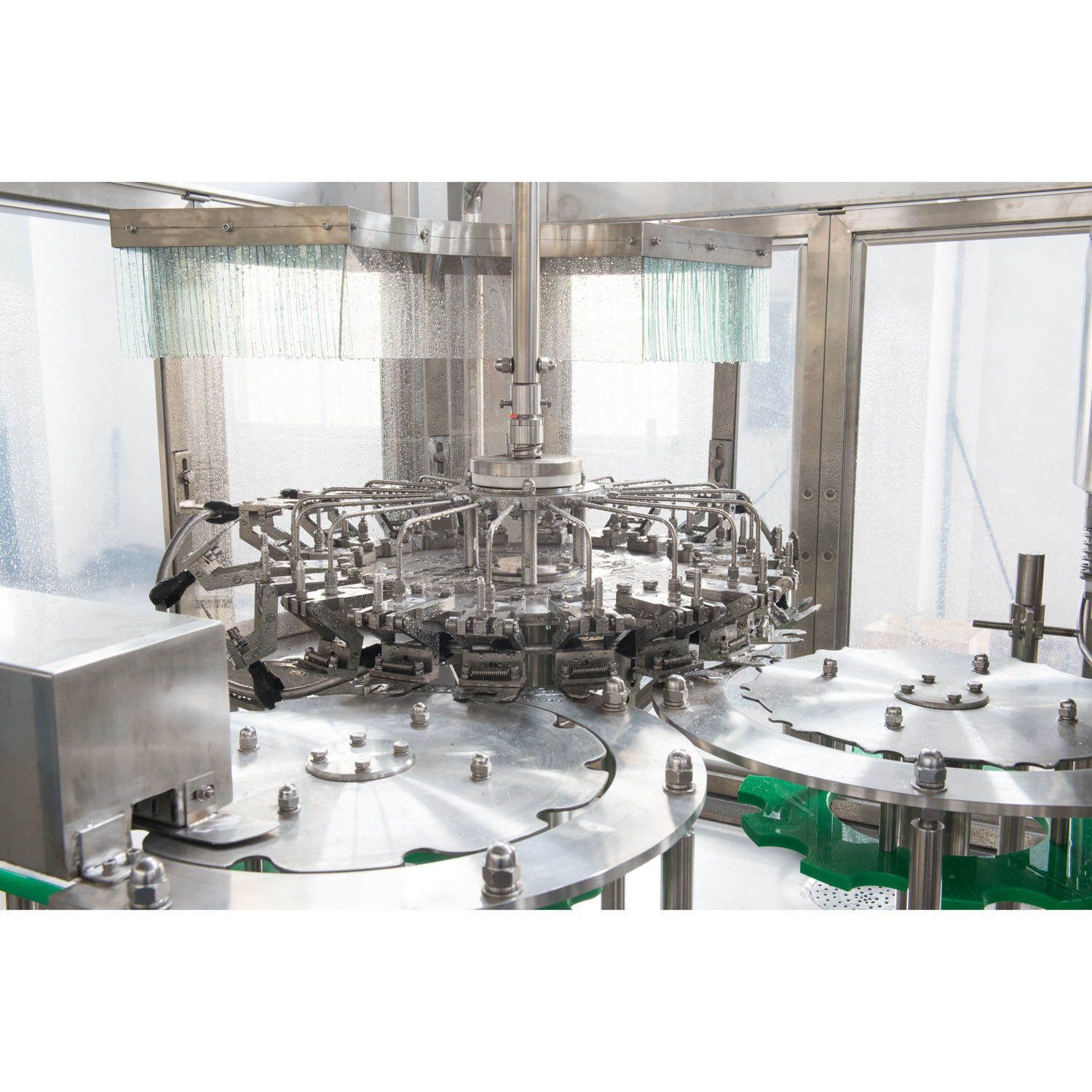

Automatic Plastic Pet Bottle Drinking Mineral Water Liquid Filling Bottling Machine

Main Features

By utilizing wind-powered technology, the wheel in the bottle is directly connected, eliminating the need for screws and conveyor chains. This makes it easier to change the shape of the bottle.

The transmission of bottles utilizes a clip bottleneck technology, eliminating the need to adjust the equipment level when changing the bottle shape. Only the curved plate, wheel, and nylon parts need to be changed.

The stainless steel clip on the bottle washing machine is specially designed to be strong and long-lasting. It does not come into contact with the screw location of the bottle mouth to prevent secondary pollution.

The high-speed large gravity flow valve filling valve ensures fast and accurate filling without any liquid loss.

When bottles are being outputted, they spiral downwards, eliminating the need to adjust the height of the conveyor chains when changing the bottle shape.

The main machine is equipped with advanced PLC automatic control technology, and the key electrical components are sourced from renowned companies such as Mitsubishi from Japan, SIEMENS from Germany, and OMRON.

Technical Parameter:

| Model | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 | CGF60-60-15 |

| Production capacity (b/h) | 2000-4000 | 5000-6000 | 6000-10000 | 10000-13000 | 13000-15000 | 15000-20000 | 20000-24000 |

| Bottle size (mm) | φ=50-110mm, H=170-310mm (Volume: 200-2000ml) | ||||||

| Main Motor power | 4.0kw | 4.2kw | 5.2kw | 6.2kw | 7.5kw | 8.2kw | 9.5kw |

| Dimension (m, L x W x H) | 2.23×1.63×2.25 | 2.6×1.965×2.25 | 2.9×2.2×2.25 | 3.88×2.2×2.25 | 3.7×3.0×2.35 | 4.5×3.5×2.35 | 5.5×4.5×2.35 |

| Weight (Kg) | 2500 | 3500 | 4200 | 6000 | 7000 | 7600 | 9800 |

Automatic Plastic Pet Bottle Drinking Mineral Water Liquid Filling Bottling Machine

Main Features

By utilizing wind-powered technology, the wheel in the bottle is directly connected, eliminating the need for screws and conveyor chains. This makes it easier to change the shape of the bottle.

The transmission of bottles utilizes a clip bottleneck technology, eliminating the need to adjust the equipment level when changing the bottle shape. Only the curved plate, wheel, and nylon parts need to be changed.

The stainless steel clip on the bottle washing machine is specially designed to be strong and long-lasting. It does not come into contact with the screw location of the bottle mouth to prevent secondary pollution.

The high-speed large gravity flow valve filling valve ensures fast and accurate filling without any liquid loss.

When bottles are being outputted, they spiral downwards, eliminating the need to adjust the height of the conveyor chains when changing the bottle shape.

The main machine is equipped with advanced PLC automatic control technology, and the key electrical components are sourced from renowned companies such as Mitsubishi from Japan, SIEMENS from Germany, and OMRON.

Technical Parameter:

| Model | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | CGF40-40-12 | CGF50-50-15 | CGF60-60-15 |

| Production capacity (b/h) | 2000-4000 | 5000-6000 | 6000-10000 | 10000-13000 | 13000-15000 | 15000-20000 | 20000-24000 |

| Bottle size (mm) | φ=50-110mm, H=170-310mm (Volume: 200-2000ml) | ||||||

| Main Motor power | 4.0kw | 4.2kw | 5.2kw | 6.2kw | 7.5kw | 8.2kw | 9.5kw |

| Dimension (m, L x W x H) | 2.23×1.63×2.25 | 2.6×1.965×2.25 | 2.9×2.2×2.25 | 3.88×2.2×2.25 | 3.7×3.0×2.35 | 4.5×3.5×2.35 | 5.5×4.5×2.35 |

| Weight (Kg) | 2500 | 3500 | 4200 | 6000 | 7000 | 7600 | 9800 |