- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-11-15 Origin: Site

In the competitive beverage industry, efficiency is not just a goal; it’s a critical component of success. For enterprises specializing in carbonated drinks, the speed, accuracy, and consistency of the bottling process can directly impact profitability and market position. As consumer demand for sodas, sparkling water, and other fizzy drinks continues to grow, beverage factories face increasing pressure to scale up production without compromising on quality. This is where modern automation, specifically the carbonated drink filling machine, becomes a game-changer.

This guide will explore how these advanced systems are revolutionizing beverage production. We will cover their core functions, the significant advantages they offer, and what to consider when selecting the right machine for your operations. By understanding the role of these machines, you can unlock new levels of efficiency, reduce costs, and strengthen your brand’s reputation in a crowded marketplace.

Table of Contents

Introduction — The Importance of Bottling Efficiency for Beverage Enterprises

What Is a Carbonated Beverage Filling Machine?

Main Advantages of Carbonated Beverage Filling Machines

Common Filling Problems and How Filling Machines Solve Them

How to Improve ROI for Carbonated Beverage Filling Machines

How to Choose the Right Carbonated Beverage Filling Machine

The Strategic Value of Automation (Conclusion)

A carbonated beverage filling machine is a specialized piece of equipment designed to fill bottles or cans with carbonated liquids like soft drinks, sparkling water, and energy drinks. Unlike standard fillers, these machines are engineered to handle the unique challenges of carbonated beverages, namely high pressure and the need to maintain a stable carbon dioxide (CO₂) level.

At its core, a complete carbonated filling line integrates several key stages into a seamless automated process. The main components typically include:

Bottle Rinsing System: Cleans and sterilizes empty bottles to ensure they are free from contaminants before filling.

Filling System: This is the heart of the machine, where the carbonated liquid is precisely dispensed into each bottle under controlled pressure.

Capping System: Immediately seals the filled bottles to lock in carbonation and prevent leakage or contamination.

Filling carbonated drinks requires managing two critical factors: high pressure and CO₂ control. To prevent the beverage from foaming and losing its fizz, these machines use a technique called counter-pressure filling. This process involves pressurizing the bottle with CO₂ to match the pressure inside the filling tank. Once the pressures are equalized, the liquid can flow smoothly into the bottle with minimal turbulence, preserving the carbonation level.

A typical production line follows a series of automated steps to transform raw ingredients into finished, packaged products:

Water Treatment: Raw water is purified to meet strict quality standards.

Liquid Preparation: The purified water is mixed with syrups, flavorings, and CO₂ in a carbonator.

Cooling: The beverage is chilled to an optimal temperature, which helps the liquid absorb and retain CO₂ more effectively.

Filling: The chilled, carbonated liquid is filled into bottles using the counter-pressure system.

Capping: Bottles are immediately sealed.

Packaging: The sealed bottles are labeled, coded, bundled, and prepared for shipment.

Modern filling machines are highly versatile and can be adapted to various packaging formats, including PET bottles, glass bottles, and aluminum cans. They are suitable for a wide range of carbonated beverages, from sodas and energy drinks to sparkling juices and hard seltzers.

Integrating an automated carbonated drink filling machine into a production line offers substantial benefits that go far beyond simply filling bottles faster. These advantages impact everything from operational efficiency and product quality to labor costs and food safety.

The most immediate benefit is a dramatic increase in production speed. Modern machines can handle thousands of bottles per hour, a rate impossible to achieve with manual or semi-automated methods. This high-speed capability allows companies to meet high market demand, especially during peak seasons. Furthermore, automation reduces downtime associated with manual changeovers, cleaning, and human error, keeping the production line running smoothly.

Consistency is a hallmark of quality. Automated filling machines use advanced sensors and controls to ensure every bottle is filled to the exact same level. This precise liquid level control not only presents a uniform, professional appearance on the shelf but also prevents under-filling or overfilling. Equally important is the ability to maintain a stable CO₂ content, ensuring that every customer experiences the same level of fizz.

Manual filling often leads to spillage, foaming, and inconsistent carbonation, all of which contribute to product loss. Automated machines are designed to minimize these issues. By precisely controlling pressure and temperature, they reduce foaming and carbonation loss. Accurate dosing systems prevent overfilling, which cuts down on overflow and waste. This increased efficiency means a higher unit output from the same amount of raw materials, directly benefiting the bottom line.

Automation significantly reduces the need for manual labor in the filling process. Instead of a large team manually handling bottles, a few skilled operators can oversee the entire automated line. This allows businesses to reallocate their workforce to more strategic roles, such as quality control, maintenance, and logistics, optimizing their human resource structure and lowering long-term labor costs.

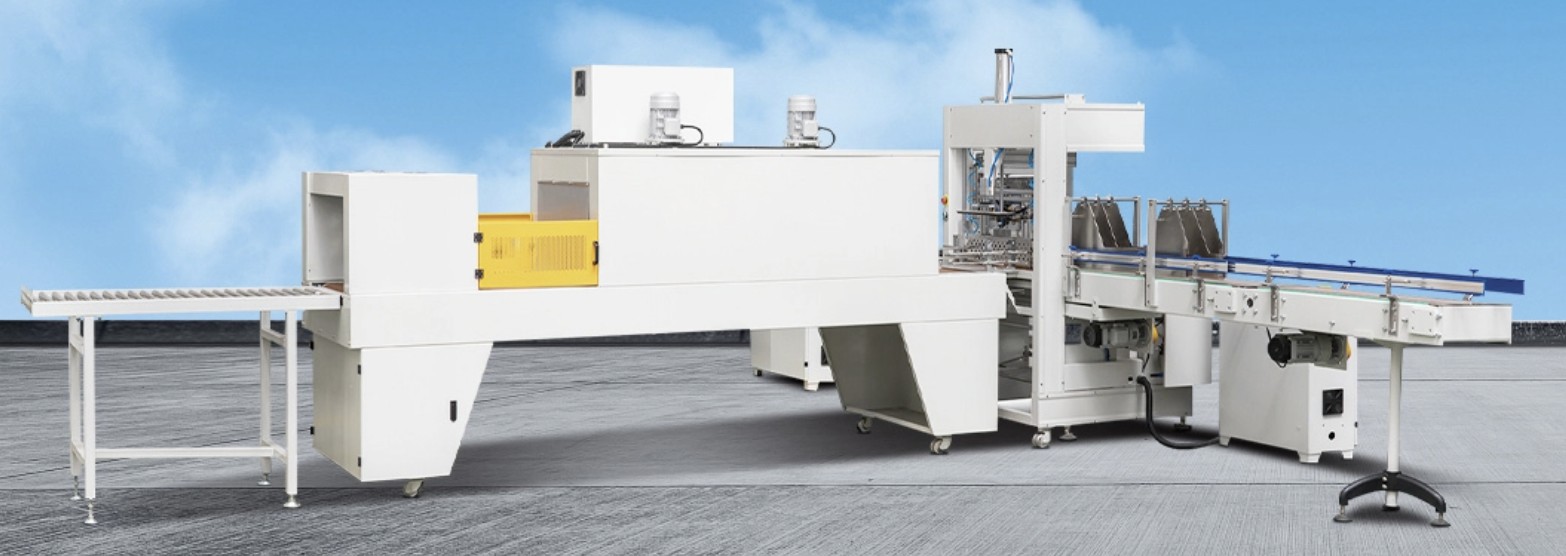

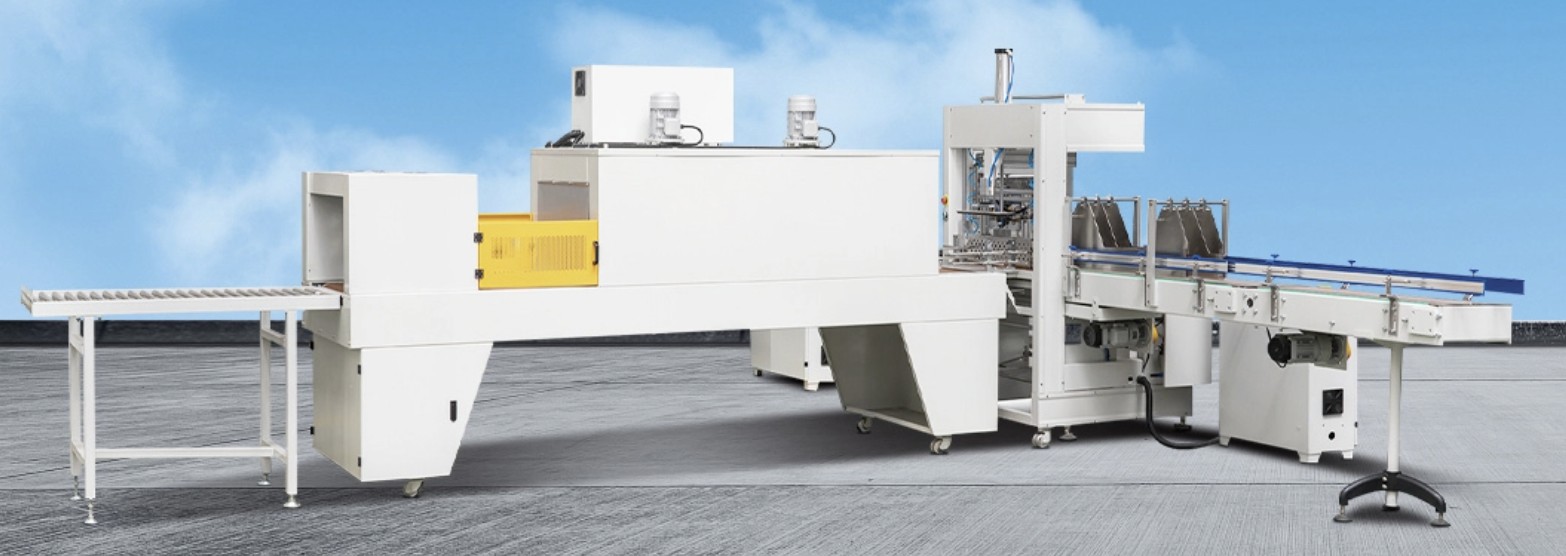

True efficiency comes from integrating the entire production process. Many modern systems are combi-blocks that combine multiple functions into one synchronized unit. This integrated equipment can handle everything from bottle rinsing and filling to capping, labeling, and packing. This seamless integration eliminates bottlenecks between stages, ensures operational consistency, and further reduces the potential for human error.

Maintaining strict hygiene standards is non-negotiable in the food and beverage industry. Carbonated drink filling machines are designed with food safety in mind. Most feature an automated Clean-in-Place (CIP) system, which allows the machine to clean and sanitize its internal pipelines, tanks, and filling heads without requiring disassembly. This ensures compliance with food safety regulations, minimizes the risk of contamination, and reduces the downtime needed for manual cleaning.

Automated filling machines are engineered to overcome the common challenges that plague manual or semi-automated bottling processes.

Severe Foaming During Filling: Solved with intelligent temperature control and stable CO₂ management, which keeps the liquid calm during filling.

Uneven Filling and Inconsistent Liquid Levels: Addressed by precision flow control systems and real-time monitoring that ensure every bottle is filled to the exact specified volume.

High Waste and Overflow in the Production Process: Minimized through automatic compensation systems that adjust for minor variations and prevent overfilling.

Frequent Equipment Downtime Affecting Output: Reduced with automatic diagnostics and modular maintenance designs that allow for quick repairs and part replacements.

Difficulty Switching Between Multiple Bottle Types: Overcome with systems that allow for quick parts replacement and multi-functional filling heads designed for versatility.

Difficulty in Hygiene and Cleaning: Solved by CIP automatic cleaning systems that eliminate the need for manual disassembly and reduce the risk of contamination.

Investing in an automated filling machine is a significant capital expenditure, but the return on investment (ROI) can be substantial and multifaceted. The key is to leverage the machine’s capabilities to maximize efficiency and quality while minimizing long-term costs.

Higher Capacity Leads to Faster Cost Recovery: The ability to produce more in less time allows businesses to meet market demand quickly and generate revenue faster, accelerating the cost recovery period.

Reduce Raw Material Waste and Lower Long-Term Operating Costs: By minimizing spillage, overflow, and product loss, these machines reduce the amount of raw materials needed per unit, leading to significant long-term savings.

Improve Product Consistency and Reduce Complaints: Consistent fill levels and carbonation boost brand reputation and customer satisfaction, which in turn reduces the costs associated with complaints, returns, and lost sales.

Intelligent Monitoring and Automatic Maintenance: Modern machines often include diagnostic systems that can predict maintenance needs and flag potential issues before they cause a breakdown, reducing costly emergency repairs and downtime.

Scalable Production Lines Bring Higher Sustainable Value: Many filling lines are designed to be modular and scalable, allowing businesses to upgrade or expand their production capacity in the future without replacing the entire system.

Selecting the right machine requires a thorough evaluation of your company’s specific needs and long-term goals. Here are some key factors to consider:

Determine Production Volume and Future Expansion Needs: Assess your current daily output, peak season demand, and any plans for future growth. Choose a machine that can meet your current needs with room for potential upgrades.

Select Suitable Bottle Types and Container Specifications: Ensure the machine is compatible with your desired packaging, whether it’s PET bottles, glass, or cans of various sizes and shapes.

Focus on Machine Automation and Compatibility: Evaluate the level of automation and how well the machine can integrate with your existing production line equipment, such as labelers and packers.

Focus on CO₂ Precision Control and Pressure Stability: For carbonated drinks, the machine’s ability to maintain precise CO₂ levels and stable pressure is paramount for product quality.

Evaluate Energy Consumption and Overall Operating Costs: Look for energy-efficient models with features that reduce water and energy use to lower your overall operating expenses.

After-Sales Service and Reliability Assessment: The manufacturer’s service capability is key. Ensure they offer reliable after-sales support, technical assistance, and a ready supply of spare parts to minimize potential downtime.

Compliance with Hygiene Standards and CIP Cleaning Design: Verify that the machine meets all relevant food safety standards and features an effective, easy-to-use CIP system.

Investing in a carbonated drink filling machine is more than just an operational upgrade; it’s a strategic move to secure a competitive advantage. These machines offer a powerful combination of efficiency, quality control, and cost savings that are crucial for thriving in the modern beverage market.

By automating the filling process, companies can produce more, waste less, and deliver a consistently high-quality product to consumers. This not only enhances brand reputation but also provides the scalability needed to adapt to changing market demands. The long-term benefits—from lower labor and material costs to improved food safety and higher customer satisfaction—make these machines a vital investment for any forward-thinking beverage enterprise. To stay competitive, it is essential for businesses to embrace automation and upgrade their production lines to meet the challenges of tomorrow.

A high-quality carbonated drink filling machine can operate 10–15 years or longer with proper maintenance. The actual lifespan depends on usage intensity, water quality, cleaning frequency, and component durability. Regular preventive maintenance helps extend the service life significantly.

For a standard filling line, installation and commissioning typically require 2–4 weeks, depending on factory layout, number of machines, and automation level. Full turnkey lines—including rinsing, filling, capping, labeling, and packaging—may take slightly longer due to integration and operator training.

Yes. Most manufacturers offer custom bottle molds, adjustable filling heads, and dedicated CO₂ control systems to accommodate unique bottle shapes or specialty carbonated beverages such as kombucha, flavored sparkling drinks, and low-sugar formulations. Customization ensures stable filling performance across unconventional designs.

Space requirements depend on machine capacity and the level of automation. A compact line may need 80–150 square meters, while a fully automatic high-speed line could require 300–600 square meters or more. Factories must also consider space for conveyors, packaging equipment, and finished product storage.

Yes. Modern filling machines are designed for seamless integration with upstream and downstream equipment, including labelers, shrink-wrappers, date coders, palletizers, and conveyors. Compatibility ensures a smooth, continuous workflow and prevents bottlenecks across the production line.