- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-05 Origin: Site

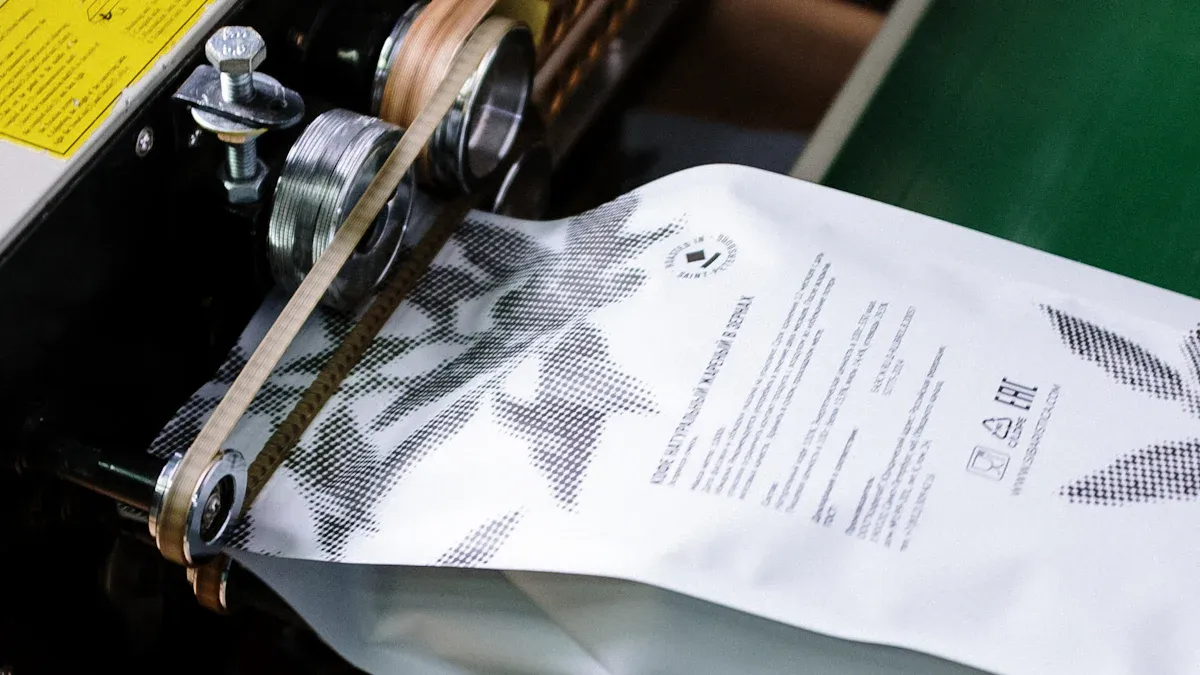

Professional packaging gives your merchandise a polished look and protects it during transport. When you use a Shrink Wrapping Machine, you can streamline your workflow and boost productivity. Automated systems often increase throughput by up to 30%, cut error rates in half, and reduce labor needs by as much as 80%. You also save on film, using up to 30% less material. These benefits help you present your products with confidence and efficiency.

Choose the right polyolefin film for your products to ensure professional packaging and protection.

Select the appropriate film thickness based on your product's weight and shape for optimal strength and appearance.

Clean and organize your merchandise before wrapping to achieve a tight seal and a polished look.

Set up your Shrink Wrapping Machine correctly to maximize efficiency and ensure consistent results.

Inspect each package after shrink wrapping to catch defects and ensure a professional presentation.

Regularly maintain your shrink wrapping machine to prevent breakdowns and extend its lifespan.

Use a shrink tunnel for high-volume production and a heat gun for flexibility in small batches.

Test your wrapping process with samples to minimize defects and ensure quality before full production.

Choosing the right polyolefin film is essential for achieving professional packaging results. The film you select affects the appearance, protection, and efficiency of your packaging process. You should consider the size and shape of your merchandise, as well as the demands of your production line.

Polyolefin shrink films come in several varieties. Each type offers unique benefits for different packaging needs.

Single-layer films provide a straightforward solution for basic packaging. You can use them for products that do not require extra strength or barrier properties. These films work well for lightweight items and simple shapes.

Multi-layer films combine several layers to enhance strength and durability. You should choose multi-layer options for heavier or irregularly shaped merchandise. These films offer better protection against punctures and tears, making them ideal for products that face rough handling.

Tip: Multi-layer films often deliver improved sealability and a tighter shrink, which helps maintain product integrity during transport.

Selecting the correct film thickness ensures your merchandise stays protected and looks appealing.

| Application | Thickness (Microns) |

|---|---|

| Shrink Wrap (Retail) | 12 – 30 |

| Lamination Films (Food/FMCG) | 8 – 20 |

| Blister Packaging | 100 – 300 |

| Vacuum Bags | 70 – 150 |

| PE Liners and Sheets | 25 – 150 |

| Anti-fog Films (Food Trays) | 20 – 40 |

Most retail shrink wrapping uses films between 12 and 30 microns. Thicker films provide more protection but may reduce flexibility.

You should match the film thickness to your product’s weight and shape. Lightweight items need thinner films, while bulky or heavy products require thicker films for added strength. For example, bottles in a beverage plant benefit from a film that balances clarity and durability.

You want to source your polyolefin film from reputable suppliers to ensure consistent quality and performance.

Folene Packaging supplies premium polyolefin shrink films with excellent gloss, clarity, and tear resistance.

SPS offers high-quality films with industry certifications, ensuring reliability for industrial use.

Note: High-quality films enhance the performance of your Shrink Wrapping Machine, resulting in better seals and a more attractive finish.

When selecting polyolefin film, keep these factors in mind:

| Factor | Description |

|---|---|

| Shrinkage Properties | Ensures a snug fit and professional appearance. |

| Film Clarity and Appeal | Improves product visibility and shelf presence. |

| Strength and Durability | Protects against damage during handling and shipping. |

| Environmental Impact | Choose recyclable and non-toxic options when possible. |

| Cost Efficiency | Balance quality with budget, considering bulk purchase savings. |

| Application Type | Match film properties to your product’s needs. |

| Sealability | Reliable sealing maintains product integrity. |

Polyolefin films stand out for their superior clarity and gloss. You will notice that your products look more appealing on shelves. The film’s strength also protects your merchandise from punctures and tears, keeping items safe during storage and transport.

Before you start shrink wrapping, you need to prepare your merchandise carefully. Proper preparation helps you achieve a tight seal and a professional finish. You also protect your products from damage and ensure that the packaging process runs smoothly.

Clean merchandise gives you the best results with shrink wrap. Dust, dirt, or moisture can weaken the seal and affect the appearance of your package.

You should always clean your products before wrapping. Use a soft cloth or compressed air to remove dust and debris. If your items have surfaces that attract dirt, pay extra attention to those areas. Moisture can also cause problems, so make sure everything is dry. Clean and dry products help you avoid weak seals and keep your packaging looking sharp.

Tip: Remove any excess or protruding parts that could puncture the shrink film. For fragile items, use padding or corner protectors to prevent damage during the wrapping process.

Organizing your merchandise makes the wrapping process faster and more efficient. Arrange your products in a way that allows you to wrap them easily. Place similar items together and line them up neatly. This step helps you avoid mistakes and saves time when you load items into the Shrink Wrapping Machine.

| Step | Action |

|---|---|

| Clean | Remove dust and moisture |

| Inspect | Check for protruding or sharp parts |

| Protect | Add padding for delicate items |

| Organize | Arrange items for easy wrapping |

How you group your merchandise affects the stability and integrity of your final package. You can choose to wrap items individually or bundle them together.

Wrapping single items works well for products that need individual packaging. You get a clean look and protect each item separately. This method suits bottles, cans, or boxes that you want to display on shelves.

Use enough film to cover each item completely.

Avoid using too much material, which can lead to excess film and a bulky appearance.

Bundling products into multipacks offers several advantages. You increase stability during transport and reduce the risk of damage. Shrink wrap tightly secures multiple items together, preventing movement and shifting. Bundled products are less likely to spill or break if dropped.

Group similar items for efficient packaging.

Multipacks create secondary packaging that adds protection and keeps products together during handling.

Note: When you group items, you make your packaging process more efficient and your products safer. Multipacks also help you present your merchandise attractively, which can boost sales.

Careful preparation sets the stage for successful shrink wrapping. Clean, organized, and properly grouped merchandise ensures that your packaging looks professional and protects your products throughout their journey.

Setting up your Shrink Wrapping Machine correctly ensures you get the best results for your merchandise. Zhangjiagang King Leader Machinery Co., Ltd. offers a Shrink Wrapping Machine designed for both beverage bottling plants and small businesses. This machine features a PLC system, a user-friendly touch screen, a compact design, adjustable speed, and a shrink tunnel with advanced hot air circulation. These features help you achieve efficient, reliable, and visually appealing packaging.

You can choose from several types of shrink wrapping machines, depending on your production needs. The table below shows the main types used in beverage bottling plants and small businesses:

| Type of Machine | Description | Volume Capacity |

|---|---|---|

| Impulse Sealers | Affordable, suitable for small volumes and products. | Low volume |

| I-Bar Shrink Wrapper | Manual device, packs around 200 items a day. | Up to 200 items daily |

| L-Bar Shrink Wrapper | Semi-auto or full automatic, suitable for thousands of products daily. | Thousands of products daily |

| Shrink Wrap Tunnels | Temperature controlled, accommodates high volume, efficient for packaging. | Tens of thousands of products daily |

Manual machines, such as impulse sealers and I-bar shrink wrappers, work well for small batches. You control the sealing and shrinking process by hand. These machines suit small businesses or startups with limited production.

Automatic machines, like L-bar shrink wrappers and shrink wrap tunnels, handle larger volumes. The Shrink Wrapping Machine from Zhangjiagang King Leader Machinery Co., Ltd. automates the process. You load the products, and the machine aligns, wraps, seals, cuts, and shrinks the film. This setup increases efficiency and consistency, making it ideal for busy production lines.

Properly loading the film onto your Shrink Wrapping Machine is essential for smooth operation. Follow these steps to ensure correct film loading:

Load the shrink wrap film onto the designated holder of the machine.

Select the right film type—polyolefin is recommended for most merchandise.

Thread the film through the rollers, following the machine’s guide.

Align the film carefully to prevent jamming or uneven wrapping.

Centerfold film comes folded in half on the roll. You place the product between the layers, which makes wrapping faster and reduces waste. Most automatic machines, including the Shrink Wrapping Machine, support centerfold film for efficient operation.

Flat film is a single layer. You may need to wrap it around the product manually or use special guides. Flat film works best for custom shapes or when you need extra control over the wrapping process.

Tip: Always check that the film feeds smoothly and stays centered. Misaligned film can cause jams or poor seals.

You must adjust the Shrink Wrapping Machine settings to match your film thickness and product pattern. This ensures a tight, clear, and professional finish.

Set the machine speed based on your production needs and film type. Thicker films and larger products may require slower speeds for proper sealing and shrinking. The adjustable speed feature on the Shrink Wrapping Machine lets you fine-tune the process for different product patterns.

Adjust the temperature according to the film thickness and material. Polyolefin films usually shrink best between 140°C and 150°C. Thicker films need higher temperatures, up to 220°C. Use the touch screen interface to set the temperature precisely.

Increase the temperature for thicker films.

Lower the temperature for thinner films to avoid burning or holes.

Always test with a sample before running a full batch.

Note: The self-developed shrink tunnel in the Shrink Wrapping Machine uses two sets of centrifugal hot air circulation. This system delivers even heat, so every package gets a consistent, smooth finish.

By following these setup steps, you can maximize the performance of your Shrink Wrapping Machine. You will achieve secure seals, clear packaging, and efficient production—no matter the size or shape of your merchandise.

Sealing and cutting the polyolefin film is a crucial step in the shrink wrapping process. You want to make sure each package looks professional and stays secure during transport. The right technique helps you avoid wasted film and ensures your merchandise remains protected.

Proper positioning of your products inside the film leads to a neat and efficient package. You should always check the alignment and minimize excess film before sealing.

You need to align your products carefully on the sealing platform. Clean items stick better to the film and create a smooth finish. Stack bundled items evenly and position them close together to reduce gaps. This method helps you achieve a tight wrap and prevents shifting during sealing.

Clean products for better film adhesion.

Stack items evenly to minimize gaps.

Align edges before sealing for a uniform look.

Using too much film can make your package bulky and waste material. You should trim the film so it covers the merchandise with just enough overlap for sealing. Avoid leaving large flaps or loose ends. This practice saves film and gives your package a polished appearance.

Tip: Position items close together and use only the necessary amount of film. This reduces waste and improves the final look of your package.

Sealing the edges of the polyolefin film keeps your merchandise safe from dust and moisture. You can use different sealing methods depending on your equipment and product type.

A sealing bar creates a straight, strong seal along the edge of the film. Lap heat sealing works by overlapping the film edges and applying heat, which forms a robust barrier against moisture and physical damage. Edge weld sealing provides an airtight and watertight enclosure, protecting your products from environmental hazards.

| Sealing Method | Description |

|---|---|

| L-Bar Sealers | Create an 'L' shaped seal, cutting and sealing the film on two sides in one motion. |

| Side Sealers | Continuously seal one side of the film, then cut and seal the leading and trailing edges. |

| Flow Wrappers | Fully enclose products in a fin seal along the bottom and end seals, often used for food products. |

| Lap Seal | Overlapping edges of the film are sealed together, providing a robust seal against external elements. |

| Edge Weld Seal | Provides an airtight and watertight enclosure, protecting contents from moisture and dust. |

You can use a quality impulse heat sealer to create tight, reliable seals. Make sure the edges of the film are aligned before applying heat. This step prevents gaps and maintains the integrity of your package. Proper sealing also adds tamper evidence and improves the overall appearance.

Package integrity: Prevents products from falling out and keeps contaminants away.

Aesthetics: Gives your package a professional look.

Tamper evidence: Shows if the package has been opened.

Efficiency: Reduces the need for rewraps and saves film.

After sealing, you need to cut the film to separate each package. The method you use depends on your production setup.

For small batches, you can cut the film manually with scissors or a blade. This method works well for custom shapes or when you need extra control. Always cut close to the seal to avoid excess film.

Automatic machines, like the Shrink Wrapping Machine, cut the film as part of the sealing process. The machine uses built-in cutters to trim the film precisely, saving time and ensuring consistency. Automatic cutting is ideal for high-volume production and delivers uniform results.

Note: Automatic cutting reduces labor and increases efficiency, especially in busy bottling plants.

Applying heat is the final step in shrink wrapping merchandise with polyolefin film. You can use either a shrink tunnel or a heat gun. Each method offers unique advantages for different packaging needs.

A shrink tunnel automates the heating process. You place your wrapped merchandise on a conveyor. The tunnel surrounds the items with controlled hot air. This method works best for high-volume packaging and delivers a professional finish.

You get consistent results with a shrink tunnel. The machine uses built-in fans and advanced hot air circulation. Every package receives the same amount of heat. This uniformity prevents shrink marks and ensures a tight, smooth wrap. The Shrink Wrapping Machine from Zhangjiagang King Leader Machinery Co., Ltd. features a self-developed shrink tunnel with two sets of centrifugal hot air systems. You achieve identical shrink wrap packages every time.

Proper air circulation is key to quality shrink wrapping. The tunnel’s fans move hot air evenly around your merchandise. This balanced heat distribution eliminates cold spots and reduces the risk of uneven shrinkage. You avoid wrinkles and get a clear, glossy finish on every product.

Tip: Use a shrink tunnel for large batches or when you need consistent, high-quality results.

A heat gun offers flexibility for small-scale operations. You hold the gun and direct hot air onto the film. This method suits custom shapes and low-volume packaging.

You control the distance between the heat gun and the merchandise. Hold the gun about 6 to 8 inches away from the film. Moving too close can cause holes or burn marks. Keeping the right distance helps you shrink the film evenly.

You must move the heat gun slowly and steadily. Sweep the gun across the surface in smooth motions. Cover all sides of the package. This technique helps you avoid uneven shrinkage and ensures a neat appearance. Heat guns may produce less uniform results than shrink tunnels, but they work well for prototypes or small batches.

Note: Choose a heat gun for small jobs or when you need portability and control.

You need to set the correct temperature and exposure time for optimal shrinkage. Polyolefin film responds best to specific heat conditions.

Set your shrink tunnel or heat gun to a temperature between 230°F and 284°F (110°C to 140°C). This range allows the film to shrink tightly without melting or burning. Thicker films may require the higher end of this range. Always test with a sample before starting full production.

| Film Type | Temperature Range |

|---|---|

| Polyolefin (POF) | 230°F – 284°F |

Limit exposure time to less than five seconds for each package. Quick heating prevents overheating and keeps the film clear and smooth. In a shrink tunnel, the conveyor speed controls exposure time. With a heat gun, you control the duration by moving the gun steadily.

Tip: Short exposure at the right temperature gives you a tight, glossy finish and protects your merchandise.

You can see the main differences between these two methods:

Shrink tunnel delivers high production speed and consistent results. You get uniform heat and a professional finish.

Heat gun is cost-effective and portable. You control the process manually, which may lead to less uniform quality and slower speed.

Shrink tunnel uses built-in fans for even heat distribution. You avoid shrink marks and get identical packages.

Heat gun may cause uneven shrinkage if you do not apply heat evenly.

Choosing the right heating method depends on your production needs. Use a shrink tunnel for efficiency and quality. Select a heat gun for flexibility and small batches. Always set the correct temperature and exposure time for the best results.

After you shrink wrap your merchandise, you need to inspect each package to guarantee quality and presentation. Careful inspection helps you catch defects early and ensures your products look professional on shelves.

Start with a visual inspection. Look for surface-level defects such as holes, tears, or uneven seals. You want the film to cover the product tightly without loose gaps. Examine the edges and corners for uniformity. If you see wrinkles or air pockets, the seal may not be secure.

Check for tight wrapping and absence of loose gaps.

Look for uniform seals along all edges.

Identify any visible irregularities or shrinkage issues.

Test the strength of each seal. Gently press along the sealed edges to confirm they hold under light stress. A strong seal keeps your merchandise protected during transport and handling. If a seal opens easily or feels weak, you should rewrap the product.

| Type of Inspection | Purpose |

|---|---|

| Visual Inspection | Detects surface-level defects |

| Mechanical Testing | Assesses strength and durability under stress |

| Seal Testing | Ensures the seal is tight and uniform |

| Shrinkage Uniformity Test | Checks for consistency in shrink wrap |

Smoothness gives your package a polished look. Run your hand over the surface to feel for bumps or wrinkles. The film should lay flat against the product. If you notice rough spots or uneven areas, adjust your wrapping process for future batches.

Clarity matters for product visibility. Inspect the film for cloudiness or distortion. Clear film lets customers see your merchandise easily. During prototyping, you can test different films and wrapping techniques to find the best clarity. Evaluate color accuracy and alignment if you use printed shrink sleeves.

| Criteria | Description |

|---|---|

| Prototyping | Fine-tune design and check for distortions |

| Color Accuracy | Assess during prototyping phase |

| Evaluation of Prototypes | Check adherence to container shapes and clarity |

Tip: Testing prototypes before mass production helps you identify and fix issues with smoothness and clarity.

Apply labels to each package. You can use hand-applied or automatic labeling, depending on your production volume. Make sure labels are straight, legible, and match your product information. Accurate labeling helps with compliance and improves shelf appeal.

Pack your shrink-wrapped merchandise into boxes for shipping or storage. Choose boxes that fit your products snugly to prevent movement. Arrange packages neatly to avoid damage. Cooling the packages after shrink wrapping ensures the seals stay tight and durable.

1. Select the right shrink film for your product. 2. Wrap the product securely. 3. Apply heat for tight shrinkage. 4. Allow the package to cool before boxing.

Note: Careful labeling and packing protect your merchandise and enhance its presentation for customers.

Shrink wrapping can present challenges, but you can solve most problems with the right approach. This section helps you identify common issues, maintain your equipment, and follow safety guidelines.

Shrink wrapping sometimes produces defects that affect the appearance and protection of your merchandise. You can spot and fix these problems by understanding their causes.

You may notice tears or holes in the shrink film. These often result from excessive heat or using film that is too thin for your product. Weak seals can also leave your merchandise exposed.

Burn holes appear when you apply too much heat during shrinking.

Inconsistent film thickness creates weak spots that tear easily.

Poor seal quality leaves gaps that can split open during handling.

Tip: Choose the correct film thickness and adjust the temperature settings on your machine. Always test with a sample before starting a full batch.

Wrinkles and creases make packages look less professional. They usually happen because of incorrect film size or uneven heat distribution.

Wrinkles and creases form when the film is too large or the machine settings are off.

Uneven shrinkage occurs if heat does not reach all parts of the package equally.

Ballooning, or air pockets, can develop if you seal the film too early.

You can reduce wrinkles by matching the film size to your product and ensuring the heat source covers the entire package.

Note: Adjust the conveyor speed and heat settings to achieve a smooth, tight finish.

Regular maintenance keeps your shrink wrapping machine running efficiently and safely. You should follow a schedule to prevent breakdowns and extend the life of your equipment.

Clean your machine often to avoid buildup that can affect performance. Wipe down the sealing bar and conveyor belt. Remove dust and debris from moving parts.

Inspect your machine for wear and tear. Check the film tension and look for signs of damage. Lubricate moving parts and test safety features.

| Frequency | Maintenance Tasks |

|---|---|

| Daily | Visual inspections, shrink wrap quality check, film tension check, lubrication, safety check. |

| Weekly | Check film unwind unit, clean sealing bar/wire, inspect conveyor belt. |

| Monthly | Inspect major components, check heating elements, inspect electrical connections. |

| Quarterly/Annual | Deep cleaning, overhaul major components, software/firmware updates. |

Scheduled maintenance helps you avoid unexpected downtime and expensive repairs. Proper operator training ensures you spot issues early and use the machine safely.

Shrink wrapping machines use heat, so you must follow safety precautions to protect yourself and your workspace.

Heat tools and shrink tunnels get very hot. You should wear safety glasses and flame-retardant gloves. Never touch the sealing bar or heating elements while the machine is running.

| Safety Precaution | Description |

|---|---|

| Read safety instructions | Always read all safety instructions and the Operations Manual before using any heat tool. |

| Fire extinguisher | Keep a fire extinguisher close by when working with heat or open flame. |

| Personal protective equipment | Wear safety glasses and gloves (flame retardant or leather suggested). |

| Clothing | Avoid loose clothing and tie back long hair while shrink wrapping. |

Alert: Stay alert and never operate the machine if you feel tired or distracted.

You need good ventilation when shrink wrapping indoors. Hot air and fumes can build up quickly. Keep the air inlet clear and make sure the workspace is free of flammable materials.

| Safety Precaution | Description |

|---|---|

| Air inlet | Never obstruct or cover the back air inlet of the heat tool to ensure proper function. |

| Clear work area | Keep the work area free of debris and flammable materials. |

| Ventilation | Ensure the work area is well ventilated when shrink wrapping indoors. |

| Wind conditions | Do not shrink wrap outdoors when wind exceeds 10 mph. |

Note: Always turn off the machine and purge any gas from hoses after use. Good ventilation and a clean workspace help you avoid accidents and keep your packaging process safe.

By understanding these troubleshooting steps, you can wrap merchandise efficiently and safely. Regular maintenance and careful operation protect your products and your team.

Wrapping merchandise in heat shrink polyolefin with a Shrink Wrapping Machine involves several key steps:

Select the right equipment and film for your products.

Set the correct temperature and airflow for even shrinking.

Test your process before full production.

Minimize defects by adjusting tension and speed.

| Benefit | Automated Process |

|---|---|

| Bottles per Hour | 600 – 1,200 |

| Productivity Increase | Up to 80% |

| Labor Cost | Reduced |

You should check sealer temperature, maintain proper tension, and keep your machine clean. Following these best practices ensures consistent results and extends your equipment’s lifespan.

You use polyolefin shrink film to wrap and protect products. It works well for bottles, boxes, and multipacks. This film gives your merchandise a clear, glossy finish and keeps items safe during shipping and storage.

Yes, you can use a heat gun for small batches or custom shapes. A shrink tunnel works better for high-volume production. You get more consistent results with a tunnel, but a heat gun offers flexibility for small jobs.

You match film thickness to your product’s weight and size. Lightweight items need thinner film. Heavy or bulky products require thicker film for extra protection. Always test with a sample before starting full production.

Wrinkles or tears often happen when you use the wrong film size or set the temperature too high. Adjust the machine settings and select the correct film width. Make sure you apply heat evenly for a smooth finish.

You should clean the machine daily and inspect moving parts for wear. Lubricate as needed and check the heating elements. Regular maintenance keeps your equipment running smoothly and extends its lifespan.

Yes, polyolefin shrink film is non-toxic and safe for food packaging. Always check that your film meets food safety standards. Use certified suppliers to ensure compliance with regulations.