- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

KLD-100

kld

Features:

1. State-of-the-art technology: The cutting tool is controlled by a motor made in Japan, ensuring a long lifespan and precise labeling.

2. Highly efficient production speed: Capable of processing 400 bottles per minute (standard size). Can be integrated into a production line or operated independently.

3. Sensor shelf for label control.

4. Versatile options: The machine head can be adjusted to accommodate round, square, elliptical, and various bottle tops and bodies. The latest dual material-providing system allows for quick material changes.

5. Innovative synchronized cutting base: No need to change the base within the specified range. If a different specification is required, it can be done in just five minutes.

6. User-friendly and safe operation: The control panel features a color-coded interface with both English and Chinese language options.

7. Cost-effective maintenance: The blades are affordable and easy to replace.

8. Durable cutting tools: The steel-connected transmission mechanism and reciprocating cutting ensure a prolonged lifespan.

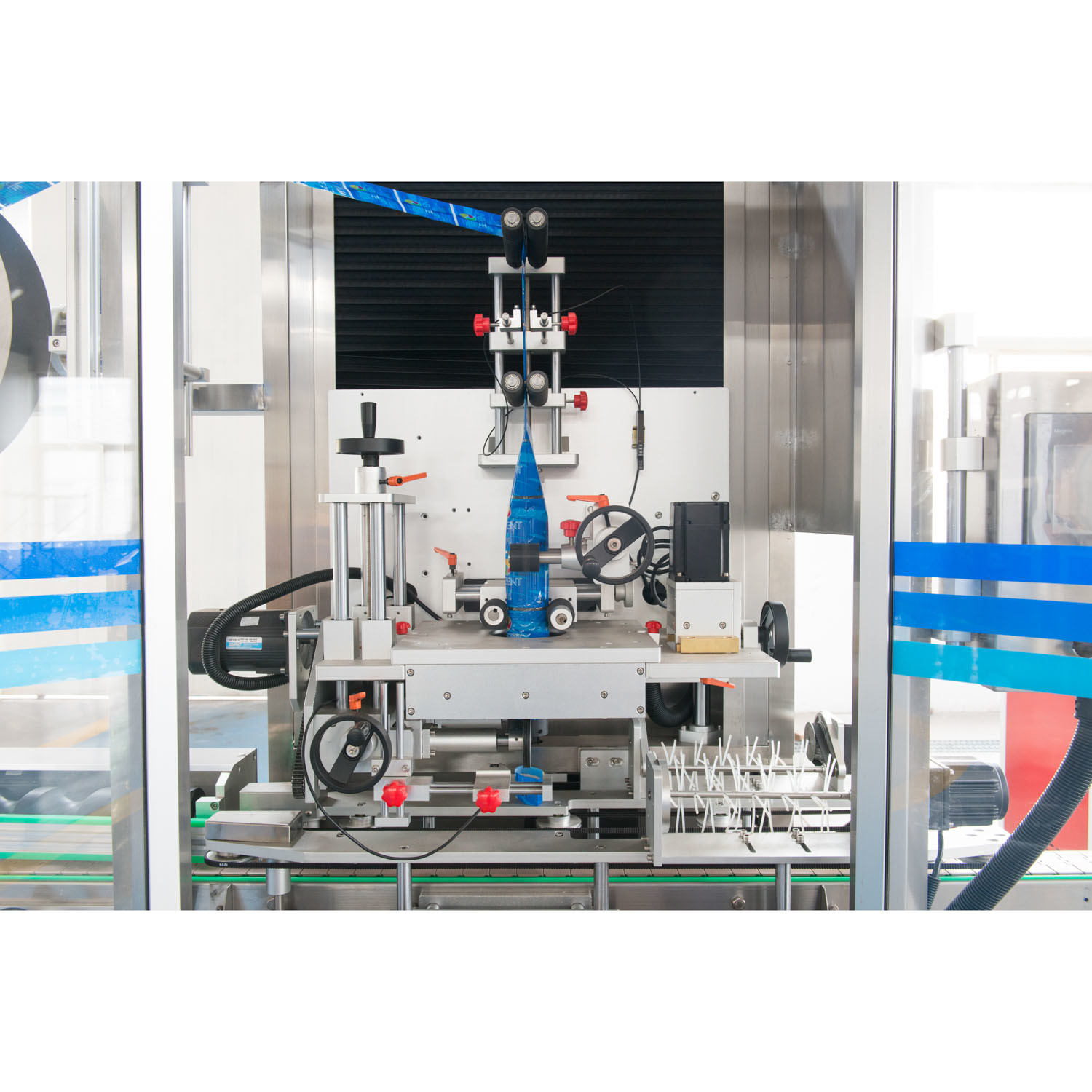

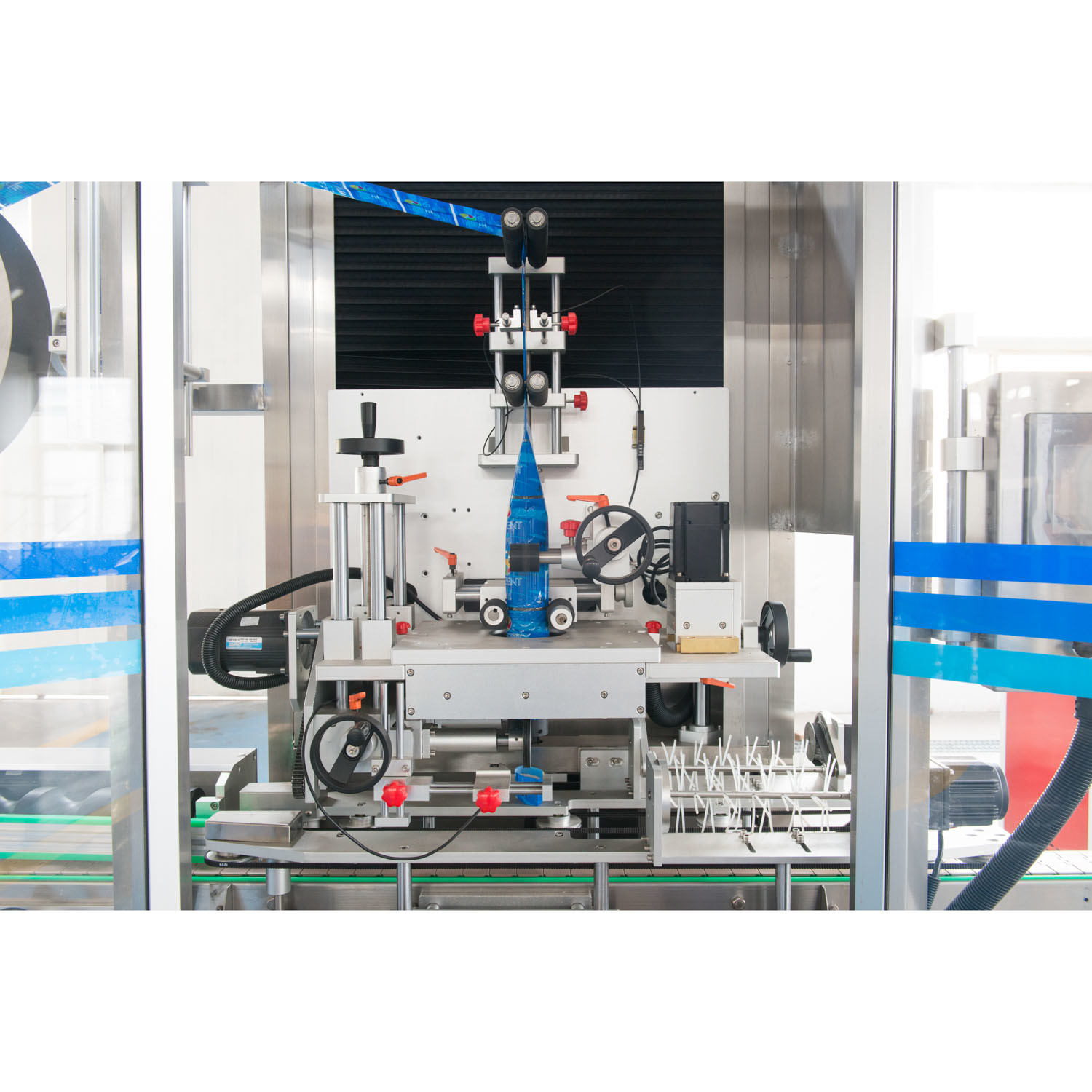

Machine Picture

Specification:

| Model | KLD-100,200,300,400,500 |

| Main engine size (length*width*height) | 2000L x 950W x 2000H(mm) |

| Main engine production speed | 10-400BPM |

| Main engine power supply | AC 3phase220v/380v |

| Bottle/Can Flat Width | 48 -185mm |

| Bottle/can materials | Glass,metal,plastic |

| Label length | 25mm -280mm |

| Label thickness | 0.03mm -0.13mm |

| Label material | PVC.PET.OPS |

| Bottle/can height | 15mm -320mm |

| Bottle/can diameter | 30.5mm -120mm |

| Bottle/can shape | round,square,oval,rectangular |

| Main engine weight | 500kg |

Features:

1. State-of-the-art technology: The cutting tool is controlled by a motor made in Japan, ensuring a long lifespan and precise labeling.

2. Highly efficient production speed: Capable of processing 400 bottles per minute (standard size). Can be integrated into a production line or operated independently.

3. Sensor shelf for label control.

4. Versatile options: The machine head can be adjusted to accommodate round, square, elliptical, and various bottle tops and bodies. The latest dual material-providing system allows for quick material changes.

5. Innovative synchronized cutting base: No need to change the base within the specified range. If a different specification is required, it can be done in just five minutes.

6. User-friendly and safe operation: The control panel features a color-coded interface with both English and Chinese language options.

7. Cost-effective maintenance: The blades are affordable and easy to replace.

8. Durable cutting tools: The steel-connected transmission mechanism and reciprocating cutting ensure a prolonged lifespan.

Machine Picture

Specification:

| Model | KLD-100,200,300,400,500 |

| Main engine size (length*width*height) | 2000L x 950W x 2000H(mm) |

| Main engine production speed | 10-400BPM |

| Main engine power supply | AC 3phase220v/380v |

| Bottle/Can Flat Width | 48 -185mm |

| Bottle/can materials | Glass,metal,plastic |

| Label length | 25mm -280mm |

| Label thickness | 0.03mm -0.13mm |

| Label material | PVC.PET.OPS |

| Bottle/can height | 15mm -320mm |

| Bottle/can diameter | 30.5mm -120mm |

| Bottle/can shape | round,square,oval,rectangular |

| Main engine weight | 500kg |